Safety

Hydrogen Detection during Cask Welding Improves Process and Eliminates Stoppages

Feb 15 2017

Project benefits

Without the H2scan Model 500 it would not be possible to detect a hydrogen build up during the cask welding process. A flash or burn-through is not only dangerous, it would cause a stoppage of the entire facility. Implementing H2scan’s analyser allowed operators to closely monitor the hydrogen concentration in real time and preemtively halt the welding process if hydrogen was present before a costly stoppage occurs.

Technical Background

- You can view the complete CASE STUDY details here.

- You can view the HY-ALERTA 500 Data Sheet here.

- You can view the HY-ALERTA 500 Manual by clicking here.

- You can view the HY-ALERTA 500 Demo Video by clicking here.

- You can view the HY-ALERTA 500 webpage by clicking here.

For further information or inquiries, please contact: Gid Herman (661) 775-9575 ext. 606 or Russell Gruener (661) 775-9575 ext. 625.

At Energy Northwest in Richland, WA an argon purge during the cask welding process was the result of a procedural change, requiring nuclear facilities to purge with an inert gas during the welding operation. As almost all combustible gas sensing technologies require oxygen to operate correctly, they cannot be implemented in the argon purged/inert environment, required for this application.

The H2scan Solution

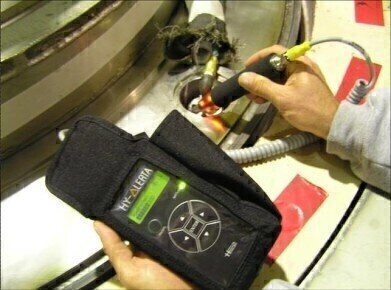

H2scan’s HY-ALERTA™ 500 Handheld Hydrogen Leak Detector does not require oxygen to operate making it the ideal solution for monitoring for hydrogen build up during the welding process. The Model 500 was used to sample for hydrogen every 10 minutes for the entire time between starting the argon purge until the lid-to-shell weld is 100% complete.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia

.jpg)