-

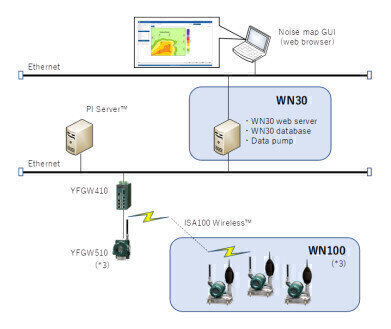

System configuration

System configuration -

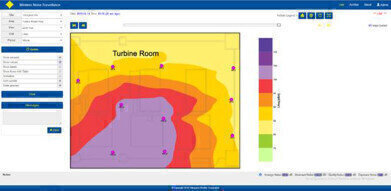

Noise map

Noise map

Safety

New wireless noise surveillance system improves HSE and productivity by enabling real-time monitoring of plant noise levels

Jul 08 2019

Yokogawa Electric Corporation has developed a wireless noise surveillance system that monitors and maps plant noise levels in real time, and is releasing this as part of its OpreXTM Measurement line-up.

This online plant noise surveillance system employs wireless technology and explosion-proof sensors, an industry first*1. Even in plants where noise levels change drastically over time, noise mapping can be applied to plan work schedules that will ensure workers do not exceed specified limits for number of work hours in a noisy environment. Through the release of such solutions, Yokogawa is helping to improve health, safety and the environment (HSE) and bolster work productivity.

In plants there are many different noise sources, and noisy work environments require measures such as limited work hours and the use of earplugs so that workers do not suffer hearing loss. Handheld sound level meters are being brought into plants to regularly measure noise levels at different locations, but actual noise levels can vary significantly between the points in time when these manual readings are made, depending on factors such as the status of the plant equipment and the time of day. To facilitate protective measures such as the creation of appropriate work schedules, there is the need for a solution that can continuously gather and analyse data in real time using readings from multiple locations throughout a plant.

In response to this need, Yokogawa began working in 2016 with Equinor ASA Norway, one of the world’s largest offshore oil and gas companies, to jointly develop an online system that monitors workplace noise levels in real time. With Yokogawa’s field wireless technology and expertise and Equinor’s extensive plant operations knowledge, the companies were able to successfully develop this wireless noise surveillance system.

Yokogawa has now acquired a license from Equinor and will begin manufacturing and selling this system.

The principal components of this system are the WN100 wireless noise meter and the WN30 noise mapping software. Compliant with the ISA100 Wireless*2 network protocol, WN100 sensors can be installed at many locations throughout a plant to measure noise levels and transmit this data in real time to servers via gateway devices such as the Yokogawa YFGW410 field wireless management station. From this data, the WN30 software can then construct in real time a noise map and superimpose this onto an actual map of the plant. Via an Ethernet connection, computers in the central control room and other key locations can then display these graphics in a web browser.

By viewing noise maps before heading to the worksite, workers can find out in real time what the noise levels will be at that location so that they can take necessary precautions such as bringing earplugs or ear muffs that are designed for the anticipated sound levels, and estimating how long they can stay in that location without experiencing hearing loss.

Occupational safety-related laws and guidelines in each country help to prevent hearing loss by limiting the number of hours personnel can be exposed to specific noise levels. Noise maps can be used to design appropriate work schedules.

This system employs ISA100 Wirelesstechnology. Compared to conventional wired systems, this system is better suited for applications where sensors must be installed over a wide area in often difficult-to-wire locations. Installation costs are lower, even with systems that have many sensors.

Kenji Hasegawa, a Yokogawa vice president who heads the IA Products and Service Business Headquarters, had the following to say about the release of this system: “In 2017 Yokogawa established three sustainability goals, one of which is to ensure the well-being of all. This wireless noise surveillance system is beneficial in helping to ensure worker health. At Yokogawa, we will keep supporting people's health and prosperity through our business activities.”

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 22 2024 Hannover, Germany

Apr 22 2024 Marrakech, Morroco

Apr 22 2024 Muscat, Oman

Apr 22 2024 Rotterdam, Netherlands

Apr 23 2024 Singapore

.jpg)