-

-

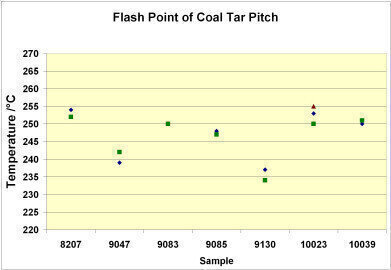

Fig. 1: Flash point of seven samples of Coal Tar Pitch tested with MINIFLASH.

Fig. 1: Flash point of seven samples of Coal Tar Pitch tested with MINIFLASH.

Analytical Instrumentation

Flash point determination of Asphalt, Tar and Bitumen by use of MINIFLASH

May 19 2010

Measuring flashpoint of asphalt, bitumen or tar is a most challenging test. Industrial coal tar pitch for example is solid at ambient temperature, softens around 100-130°C and becomes fully liquid at 180°C. When cooled down the tar sample becomes rock solid in seconds, making it difficult to clean flashpoint testing equipment and to continue with the measurements. The MINIFLASH flashpoint tester from GRABNER INSTRUMENTS offers a smart solution to test even problematic coal tar pitch samples with excellent repeatability.

Tar is used for a variety of industries. E.g. for aluminium production, coal tar pitch is mixed with petroleum coke and baked at high temperatures to produce anodes and cathodes for smelting aluminium. Combustible coal tar pitch also poses a risk to the health of industry workers, if inhaled during the production process. When heated or incinerated, coal tar pitch produces hazardous odours. For safety reasons it is therefore of critical importance to observe the flash point of tar samples. This is best done by testing flashpoint in a sealed cup without an open flame, using the least possible amount of sample to ensure that no hazardous fumes are spreading.

MINIFLASH versus Open Cup

In general the open cup method is used for testing tar, bitumen and asphalt samples at high temperature. The drawbacks of this method are evident especially when used for coal tar pitch: A large amount of sample (70mL) is heated in an open sample cup, so a harmful concentration of hazardous airborne particles can form and spread quickly. Open cup flashpoint measurements do not produce highly reproducible results, and the cleaning of the big cups is a time consuming and cumbersome thing to do.

The Grabner MINIFLASH flashpoint analyzer on the other hand is using only 1 mL of sample and tests the flashpoint in a completely closed cup. The flashpoint is detected via a patented method, without an open flame. The small sample cup guarantees faster heating of tar samples and easy cleaning. The fast sample throughput and an improved repeatability make the MINIFLASH an unmatched analyzer for this application.

The MINIFLASH flash point analyzer from GRABNER INSTRUMENTS has become known as the safest, most reliable and most versatile flashpoint tester on the market. Because of the automatic and easy operation of the analyzer no operator bias is encountered, fast thermoelectric heating and cooling guarantees best available sample throughput.

All measurements are performed according to the advanced methods ASTM D6450 and D7094, yielding results equivalent to ASTM D93, D92, D56 and ISO 2719 standards. Fast measurements, a very good repeatability and an easy cleaning procedure make the GRABNER INSTRUMENTS flashpoint analyzer a superior analyzer when testing the flash point of tar, asphalt or bitumen samples.

For further information on the GRABNER INSTRUMENTS MINIFLASH turn to www.grabner-instruments.com or request the application note via info.grabner-instruments@ametek.at

Digital Edition

PIN 25.2 Apr/May

April 2024

In this Edition Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector...

View all digital editions

Events

May 08 2024 Lahore, Pakistan

May 13 2024 New Orleans, LA, USA

May 14 2024 Tashkent, Uzbekistan

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Lund, Sweden