Measurement and Testing

World Class Flashpoint Testing at your Fingertips

Dec 24 2010

Grabner Instruments (Austria) launches Miniflash Touch; its new portable tester for easy and safe flash point testing. The analyser incorporates the well known advantages of the Grabner Instruments flash point method in a new colourful touch-screen design, which runs on a Microsoft® Windows® platform. It offers full compatibility with network, PC and LIMS, new flashpoint methods and has unique features for standard and advanced users.

Miniflash flash point testers work according to ASTM D6450 and D7094, which give results equivalent to the Pensky Martens ASTM D93*) / EN ISO 2719 and Tag ASTMD56closed cup methods. The new Miniflash Touch analyser features improved methods for EN ISO 3679 (Go/No Go Method) and EN ISO 3680 (equilibrium method) and reinforces its position as standard flashpoint analyser for testing hazardous goods according to transport regulations. Miniflash Touch facilitates controlling of the parameters heat rate, ignition energy and amount of atmospheric oxygen present in the combustion chamber, through which advanced users can simulate virtually every flashpoint method within varying environmental conditions. The new model allows testing at an extended temperature range, from 0-400°C and provides easy cleaning, by introducing a new automatic ignition cleaning method.

Miniflash Touch’s large colour touch-screen runs in a Microsoft® Windows® environment. This enables easy networking and data transfer and allows seamless LIMS integration via Ethernet, LAN, RS232 and USB and full remote operation of the analyser. Further highlights of the flash point tester are USB printer support, intuitive menu navigation and a vast program and data storage. The unique flash point combustion graphics give users the opportunity to follow every millisecond of the flash combustion in unprecedented detail.

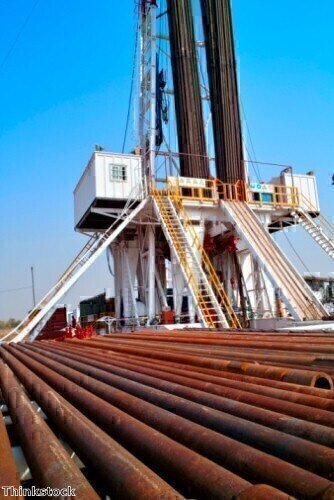

Grabner Instruments’ portable Miniflash testers are known for maximum safety, accuracy, speed and ease of use in testing flashpoints of liquids and solids. The extremely versatile analysers are worldwide standard testers for the petrochemical industry.

The flash detection method measures the instantaneous pressure increase of only 1-2 ml sample inside a continuously closed chamber at flashpoint temperature; eliminating the need of testing with an open flame. The fast thermoelectric cooling after the test saves expensive labour time and is optimised to guarantee best life time of temperature control. Miniflash models are available for single tests or with an 8-position auto sampler for continuous flashpoint testing.

Digital Edition

PIN 25.2 Apr/May

April 2024

In this Edition Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector...

View all digital editions

Events

May 06 2024 Riyadh, Saudi Arabia

May 06 2024 Houston, Tx, USA

May 06 2024 Houston, Tx, USA

Canada Gas & LNG Exhibition & Conference

May 07 2024 Vancouver, BC, Canada

May 08 2024 Lahore, Pakistan