-

-

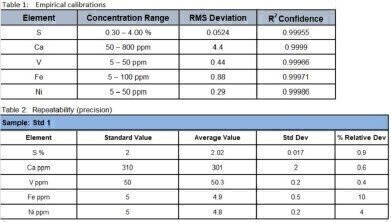

See Table 1: Empirical Calibrations. See Table 2: Repeatability (Precision)

See Table 1: Empirical Calibrations. See Table 2: Repeatability (Precision) -

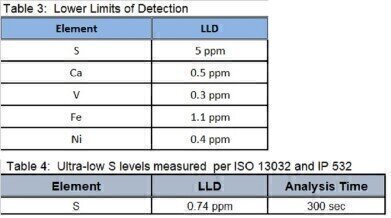

See Table 3: Lower limits of detetion. See Table 4: Ultra-low S levels measured per ISO 13032 and IP 532

See Table 3: Lower limits of detetion. See Table 4: Ultra-low S levels measured per ISO 13032 and IP 532

Analytical Instrumentation

N, Va, S in crude by EDXRF

Dec 13 2018

Sulfur, vanadium and nickel occur naturally in crude oil, and their concentrations vary depending on the geographic region of the oil deposits. Depending on the region, some crude may also contain measurable levels of calcium and iron. High metal content can foul the refining process during cracking, so low metal crude is desirable. At the refinery - as well as midstream at pipelines, transportation, and gathering points, and during blending - a quick and easy means of screening and monitoring the metal content is a valuable tool in characterising the quality of the crude before refining. Also, new NYMEX/CME specifications limiting nickel to 8 mg/kg max and vanadium to 15 mg/kg max requires reliable measurement into the low single digit mg/kg levels.

ICP (Inductively Coupled Plasma) is a complex technique requiring careful, often time consuming measurement methods. Frequent calibration and instrument maintenance can require a more technically expert operator, and care must be taken to ensure a clean nebulizer and proper flow of external gasses. These challenges combine for relatively long sample preparation and measurement times - sometimes more than one hour per sample - and relatively high daily cost and cost per sample.

Applied Rigaku Technologies offers the NEX DE EDXRF (Energy Dispersive X-ray Fluorescence) spectrometer to ease these challenges and provide measurement results for low levels of vanadium, nickel and other metals, as well as sulfur analysis. Simple to operate, the system can be used by non-technical operators, with measurement times of less than ten minutes per sample. Sample prep is also straightforward and quick; simply homogenize the sample and fill a 32mm XRF sample cup with approximately 4.0g of oil for direct, non-destructive measurement of the sample. External gasses are not required for measuring crude and residual oil, making daily running costs very low and cost per sample on the order of one dollar-just the cost of a sample cup and X-ray film.

Using Applied Rigaku Technologies model NEX DE, the metals in crude and resid can be measured from the 100s of ppm to single digit ppm levels. NEX DE uses a unique combination of high throughput SDD detector capable of 500,000+ cps count rate collection with special X-ray tube filters that remove background in the regions of interest for very low detection limits. Calibration is a simple one-time procedure using a set of commercially available standards and stepping through the Rigaku flow bar software design, again adding to the ease of analyzer operation.

Some typical data are presented here to demonstrate the performance of Rigaku NEX DE.

Empirical calibrations were built using a suite of 10 commercially available mineral oil calibration standards that represent crude, residual oil, bunker fuel and other heavy hydrocarbon oils. See Table 1

To demonstrate repeatability (precision), a sample is measured for 10 repeat analyses without moving the sample between measurements. See Table 2.

Ten repeat analyses of a blank mineral oil sample are taken with the sample in static position, and the standard deviation (s) is determined. The LLD is then defined as 3s. Shorter measurement times can be used if such low detection limits are not required. See Table 3

For sulfur analysis NEX DE can be used to measure the high levels found in crude and resid by ASTM D4294 in air. With simple connection to helium purge, ultra-low levels can be measured as per ISO 13032 and IP 532. See Table 4

The Rigaku NEX DE analyser gives technical and non-technical operators alike a simple yet powerful and versatile system for quantifying multi-elemental composition and NEX DE achieves excellent performance for monitoring sulfur and metals in crude, residual oil, bunker fuel and other heavy hydrocarbon oils.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 22 2024 Hannover, Germany

Apr 22 2024 Marrakech, Morroco

Apr 22 2024 Muscat, Oman

Apr 22 2024 Rotterdam, Netherlands

Apr 23 2024 Singapore