Analytical Instrumentation

Safe GC solution for the sampling & analysis of liquefied gases

Oct 19 2016

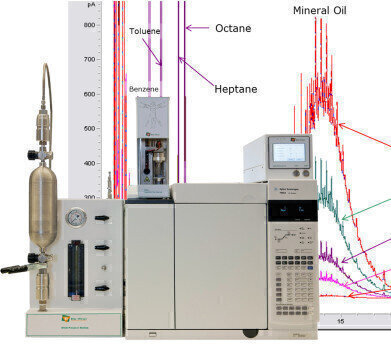

The sampling and analysis of impurities and contaminants in liquefied gases is a challenge. To eliminate the need for evaporation of the liquefied gas and to overcome the discrimination and adsorption effects Da Vinci Laboratory Solutions has developed the Liquefied Gas Injector ASTM D7756. This gas chromatographic (GC) method features a safe injection of the liquefied gas directly onto the GC column and a representative sampling through a pressure station.

Proven Injection Technology

The direct injection approach of the Liquefied Gas Injector (LGI) includes the proven fuel direct injection technique used by the automotive industry to inject fuel into the automotive engine combustion chamber.

The LGI is connected to a standard GC injector needle, which is inserted into a GC large volume on-column injection system. Solenoid activation transfers the pressurised sample through the needle directly on-column. A sliding device moves the needle downwards for the injection and upwards for purging.

Since its introduction in 2010 the LGI has been successfully used by a global installed base of leading oil refineries.

Representative Sampling

To allow a representative sample injection a Pressure Station is used to keep the sample in a liquid phase during the injection. The sample cylinder is installed using quick connectors. For liquid samples the Pressure Station adds high pressure Nitrogen to the sample cylinder and controls the outlet pressure and flow.

Optionally the Pressure Station can also be configured for gas samples by including a vaporizer to control the sample evaporation after injection. The waste sample is vented to a central waste system to ensure laboratory safety.

Wide Application Range

The DVLS Liquefied Gas Injector offers laboratories a proven GC standard for the following applications:

- Oily residues and light contaminants in LPG (ASTM D7756, EN 16423)

- Hydrocarbon composition of LPG (ASTM D 2163, ISO 7941)

- Sulfur compounds in liquefied petroleum gases

- Desulfurization additives in LPG: DIPA, MEA & DEA

- Inhibitors, additives and Dimers in Butadiene: ACN, ρTBC, Butadiene Dimer

- Nitrogen, carbon dioxide, hydrogen sulfide and hydrocarbons in unstabilised gas condensate.

Accurate and Fast Performance

Several case studies demonstrate an excellent and fast performance of the LGI. The case studies are described in the various application notes. One of the application notes describes the use of the LGI-GC technique for the analysis of sulfur compounds in liquefied Propane and Butane samples and in a liquid Pentane sample.

Using a FPD detector the limits of quantification (LOQs) range from 0.18 to 0.27 mg sulfur/kg and the limits of detection (LODs) from 0.05 to 0.08 mg sulfur/kg respectively. This demonstrates that the LGI-GC technique combined with a sulfur specific detector offers a powerful tool for sulfur control of liquefied petroleum gas samples and liquid pentane samples.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia