Measurement and Testing

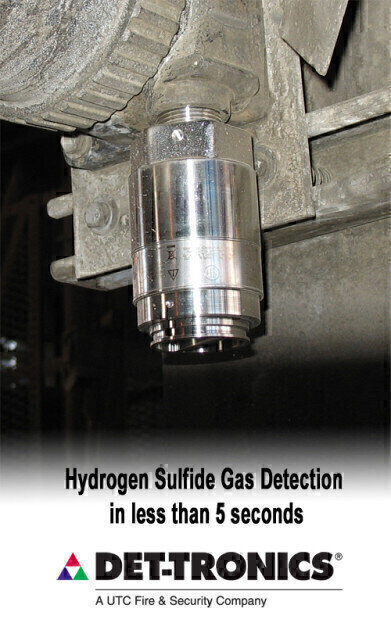

Hydrogen Sulfide Gas Detection in Less Than Five Seconds

Jun 23 2010

The Det-Tronics NTMOS hydrogen sulfide (H2S) detector can detect H2S in less than five seconds – six times faster than the ISA standard. In addition, the detector operates well in harsh environments that include extreme temperature and humidity. The detector’s speed of response is essential because high concentrations of H2S can cause instant death, while relatively short-term exposure to 500-1000ppm can be life-threatening and cause serious harm.

"Our ultra-fast H2S gas detector uses nanotechnology (NT) in a Metal Oxide Semiconductor (MOS) sensor to help reduce the occurrences of hydrogen-sulfide injuries and deaths," said Cliff Anderson, Marketing Director at Det-Tronics. “Our detector alerts people to the presence of hydrogen sulfide in less than half the time of other detectors. And the onboard humidity and temperature sensors ensure accurate and repeatable readings."

Third-party tested to ISA-92.0.01, the Det-Tronics NTMOS H2S gas detector senses hydrogen sulfide in conditions that might damage standard electrochemical and standard MOS sensors. The Det-Tronics NTMOS detector is packaged in a rugged housing, protected by a sintered stainless steel flame arrestor, and can be installed in Class I, Division 1 locations. The NTMOS gas detector can be installed as a stand-alone detector or combined with a display for local indication.

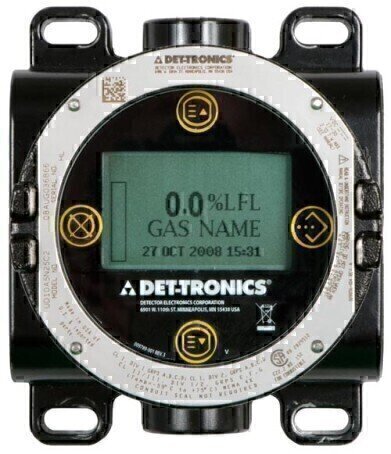

Det-Tronics’ FlexVu® Universal Display is an effective display to pair with the NTMOS detector. The FlexVu display provides non-intrusive calibration, local event logging, and third-party performance certifications. This display/communicator reduces spare-parts inventory by working with a wide spectrum of toxic and combustible gas sensors and by operating with industrial communication protocols such as HART and Modbus.

Because the FlexVu Universal Display provides non-intrusive magnetic calibration and configuration, a single person working alone can calibrate gas detectors without declassifying a hazardous area. In addition, the FlexVu display has been third-party performance tested and certified to FM, CSA, and ATEX/IEC. Its reliable construction has an explosion-proof rating and is approved for use in Class I, Division 1, Groups A, B, C, and D classified hazardous areas for all gas types.

"The FlexVu intuitive menu structure simplifies operation by enabling quick device set up and easy access to sensor status information including local alarm and event logs," said Mike Bragg, Product Marketing Manager at Det-Tronics. “Plus users will like the backlit, heated LCD that clearly displays gas concentration, and alarm and fault status."

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia