Measurement and Testing

A turnkey solution for reliable and easy CO2 quality control

Dec 13 2018

Carbon dioxide (CO2) is a colourless, odourless and inert gas produced by all aerobic organisms through respiration. Fermentation of sugars and combustion of wood, fossil fuels and other organic materials are also among CO2 main natural sources.

CO2 is a commonly used additive in the food and beverage industry (e.g. for soft drink, brewery, and champagne carbonation). Its fabrication process, that can be natural or chemical, can lead to the presence of impurities such as Benzene, Toluene, Ethylbenzene, Xylenes (BTEX) as well as sulfur compounds (H2S, Methyl-Mercaptan, Ethyl-Mercaptan, Dimethyl Sulphur, Diethyl- Sulphur, Dimethyl Di-sulphur, SO2, COS, CS2 and more).

To ensure people’s safety, limit values of these impurities have been set by various health and safety regulations. These determine that speciation of each impurity must be done if Total Sulphur (TS) concentration is over 0.1 ppm v/v.

Gas Chromatography (GC) is one of the most commonly used techniques for CO2 quality and purity monitoring to ensure meeting legal requirements in such complex matrix. Indeed, it is important to provide reliable solutions to monitor specific molecules with capabilities of data validation.

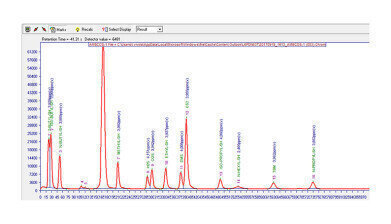

Chromatotec® has developed a GC analytical system for impurities measurement in CO2. It consists of a fully independent and automatic cabinet including several modules, one of which is the chromaS-COS, a 5U module for TS analysis. The chromaS-COS analyses H2S, mercaptans, DMS, DMDS, COS, CS2 and SO2 in just 10 minutes thanks to metallic capillary chromatography columns and a dual Flame Photometric Detector (FPD) using a filter specific to sulphur compounds.

This sensitive instrument, with a sampling loop of 250 μL, can detect concentrations ranging from 1 ppb to 100 ppm and has a Limit of Quantification (H2S) below 10 ppb. Reliable results are now obtained for up to 16 compounds in a single analysis of CO2 from producers such as Messer or Air Liquide, without any interferences or coelutions.

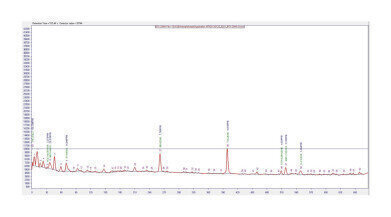

The airmoVOC BTEX is Chromatotec’s 4U module for acetaldehyde and BTEX analysis in 1200 s using a Flame Ionisation Detector (FID). This unit is MCERTS certified for benzene measurement following EN 14662-3 (2013) and TÜV certified for BTEX analysis (1996), with a limit of quantification (acetaldehyde)< 5ppb.

Digital Edition

PIN 25.2 Apr/May

April 2024

In this Edition Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector...

View all digital editions

Events

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia

May 06 2024 Houston, Tx, USA

May 06 2024 Houston, Tx, USA