Measurement and Testing

Mobile Shift Operations Management System

Aug 16 2013

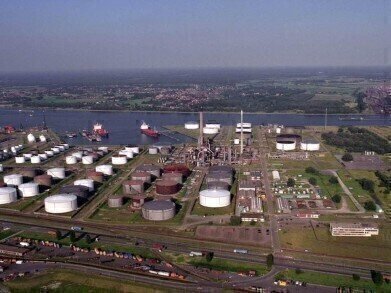

Mobile eSOMS is being used at the Independent Belgian Refinery (IBR) in Antwerp to deliver improvements to process data collection procedures. Four teams of 18 operators now use this highly effective system to digitally record and automatically transfer data from around the site, making it available to necessary systems and personnel to ensure processes are optimised and the plant is running at best efficiency.

Mobile eSOMS can be used on the latest mobile devices. It replaces a previous paper-based system at IBR, increasing operational efficiency and enabling the collection of more data to bring further process and maintenance improvements at the refinery. This includes regular collection of temperature and vibration data on compressors, providing information to enable predictive maintenance to keep the plant running smoothly.

The eSOMS solution was initially trialed on a small desulphurisation unit and is now utilised on all equipment across the IBR site. The efficiency of data collection, data transfer and integration into other systems provides process engineers with a clear view of processes across the refinery, giving them the information they need to analyse and initiate any improvements required for best operation.

eSOMS provides a flexible solution for IBR with freedom to program for their specific requirements. Marc Van den Bossche, Assistant Asset Team Leader at IBR commented, “eSOMS has helped us to better integrate site operations and reduce the risk of human error. The increased efficiency with which we can carry out routine duties means we are able to collect additional data which will help to optimise processes and maintenance across the refinery.”

Ventyx, an ABB Company (USA), has designed eSOMS based on detailed understanding of the challenges in achieving the best efficiency, safety and reliability for the operation and maintenance of facility assets. It is a modular solution with a wide array of features available to meet varying site requirements, including RFID tags to ensure correct locations for readings, a Notice of Change system incorporating an audit trail which meets regulatory requirements, task tracking for easy compliance reporting, management of equipment identification and configuration control. It ensures efficient, error-free data sharing between systems by reducing manual data entry requirements. The system is ideal for recording and confirming the status of safety equipment and provides quick access to equipment data of critical importance to plant safety.

Digital Edition

PIN 25.2 Apr/May

April 2024

In this Edition Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector...

View all digital editions

Events

May 06 2024 Riyadh, Saudi Arabia

May 06 2024 Houston, Tx, USA

May 06 2024 Houston, Tx, USA

Canada Gas & LNG Exhibition & Conference

May 07 2024 Vancouver, BC, Canada

May 08 2024 Lahore, Pakistan