-

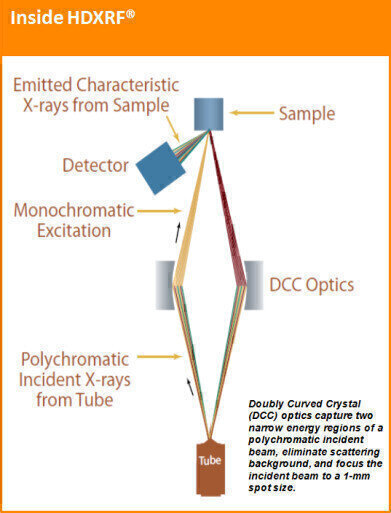

Figure 1. HDXRF Engine configuration

Figure 1. HDXRF Engine configuration -

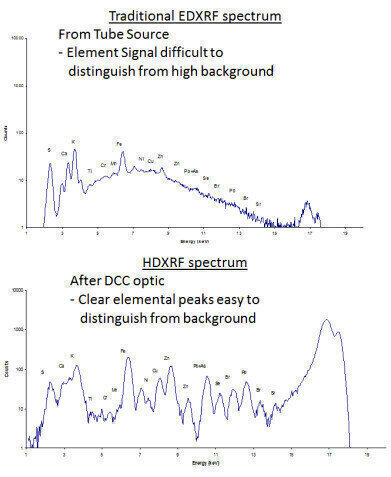

Figure 2. Traditional EDXRF spectrum vs. HDXRF spectrum

Figure 2. Traditional EDXRF spectrum vs. HDXRF spectrum -

Analytical Instrumentation

Elemental Analysis in Petroleum Products

Mar 31 2016

When thinking of elemental analysis in petroleum products, sulfur is often the first thing that comes to mind. Chlorine is another element that is commonly tested for in refineries to monitor and prevent corrosion of equipment. However, these are not the only elements that are important to monitor at a refinery.

Opportunity crudes can cost 5-30% less than WTI and provide the refiner with the ability to increase margin. However, the quality of opportunity crudes can vary significantly, even from the same source. So, monitoring elemental composition of incoming crude quality allows for process optimization and also allows the refiner to reap savings more efficiently:

- Catalyst Optimization: Measuring feed to the cat cracker for elements like vanadium, nickel, phosphorus, and iron can help to optimize cat cracker operation. These elements are known catalyst poisons and can significantly shorten catalyst life. Monitoring for catalyst poisons can reduce down time of the FCC and optimize catalyst addition. Spent catalyst, especially if it did not meet the life expectancy, can be analyzed to determine if elemental poisons contributed to the shortened life.

- Lube Oil Testing: Additive packages are used in lubricant manufacturing to enhance lube oil performance and to help prevent possible mechanical failure due to excessive wear or heat. Some additives can include barium, calcium, phosphorus, copper, and zinc compounds.

- Used Lube Oil (Wear) Testing: Monitoring suspect metals in lubricating oil can help determine whether servicing or maintenance of the system is needed. Identifying trends and detecting trace amounts of wear metals can help to reduce maintenance and prolong engine or machine life.

There are endless opportunities where multi-element analysis in petroleum products can offer value. This type of testing is becoming more and more common and can help contribute to running a more efficient refinery with an improved bottom line!

Frequent testing for multiple elements with a third party test lab can quickly become costly. In order to efficiently quantify heavy metals in various petroleum products at a frequency which can offer the most impact, first-party on-site testing is the best bet.

X-Ray Fluorescence (XRF) technology has been a standard in the petroleum business for many years. However, multiple element analysis sensitivity can be challenging with standard technology. The introduction of XOS-patented doubly curved crystal (DCC) optics to an Energy Dispersive XRF system delivers the HD Maxine powered by High Definition X-ray Fluorescence (HDXRF) which surpasses traditional limits of EDXRF for many heavy elements.

Let’s Get Low

An HDXRF analyzer engine consists of a low-power X-ray tube, multiple point-to-point focusing optics for excitation, a sample cell, and an X-ray detector. In this system, shown in Figure 1, the diffraction-based DCC optics capture a wide angle of X-rays from the X-ray tube and focus multiple narrow energy bands of X-rays to a small spot on the sample cell surface. The monochromatic primary beams excite the sample and secondary, characteristic fluorescence X-rays are emitted. Those secondary X-rays are processed by the detector and elemental composition of the sample is reported by the instrument.

The analyzer’s engine does not require consumable gases or high temperature operations. Since monochromatic excitation means that background from the incident beam (X-ray tube source) is drastically reduced, the signal-to-background ratio (S/B) on the HD Maxine is improved over traditional EDXRF. Elements that would have otherwise gone undetected in the background are now possible to quantify with HDXRF as illustrated in Figure 2. Multiple monochromatic excitation beams also mean that multiple areas on the energy dispersive spectrum have the best possible resolution.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia