Analytical Instrumentation

Real-Time Remote Determination of Saybolt Fuel Color in Industry 4.0 Plants

Apr 15 2020

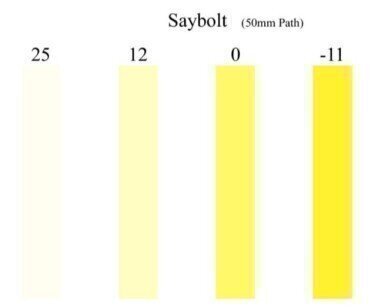

In today's world, remote operations have never been more necessary. Plants with Industry 4.0 agendas can use a Saybolt Color Analyser to assist in automating their product quality by measuring and controlling fuel color changes remotely and in real-time. Without hands-on sampling, this ‘set-and-forget’ system provides a color analysis of process samples from -16 (dark) to +30 (light) in seconds.

Detecting fuel color changes is often used for quality control purposes because it is an easy, rapid determination of product quality or contamination. Refineries with Industry 4.0 agendas can meet connectivity requirements by automating their process with a Saybolt Color Analyser system.

By sampling directly from the process stream, the Guided Wave Saybolt Analyser system, reports the fuel color measurements directly to the DCS or PLC utilising Modbus communications over Ethernet TCP. Process Engineers receive updates on current fuel colour conditions instantaneously in real-time and can then adjust the process to ensure that product specifications are maintained. This is extremely important for tankless refineries that run on the margins.

Confirmed to ASTM Standards - ASTM-D156, ASTM D6045

In the past monitoring refined fuel colour changes was accomplished by a grab sample technique or required an observer to compare the color of a product sample to a known standard, and then judge the “colour”. This one-point-in-time sampling method along with human interpretation leaves room for error and inconsistencies. Now, with Guided Wave’s Saybolt Colour Analyser critical lab-quality data is confirmed to ASTM Standards (ASTM D156, ASTM D6045) without a lab.

Built on Guided Wave’s proven multi-wavelength ClearView® db technology this filter photometer is a dual-beam design that provides increased stability and higher accuracy over other single-beam photometers.

The Complete “Ready-to-Go” Analytical System Includes:

- 1) Saybolt Analyser (dual-beam ClearView db photometer platform)

- 2) Fiber Optic Cables (to remote the analyser electronics from the sample point)

- 3) Sample Interface (probe or flow cell)

- 4) Control Software (built-in and pre-calibrated)

Get a Saybolt Analyser System with FREE Sample Interface and Fibers

For a limited time, Guided Wave is offering its Saybolt Analyser including a free flow cell and the fiber optic cables. Fibers and the flow cell supplied are based on a standard configuration. Other configurations are available on request.

Request your Quote Now and Lock in the Promotional Price and Savings

With these uncertain times, we understand it may be hard to commit to purchasing soon. However, get your quote now and lock in this special promotional price, even if you buy later. Your quote with lower prices will be honored through the end of 2020. Remember there is no obligation to buy. Simply request a quote by May 31st to get these savings and buy before December 31, 2020.

Don’t miss this money-saving opportunity. Click here to receive a Saybolt Promotional Quote or to see the datasheet with specifications. For a free appliecation review or other questions email us.

Typical Refined Fuel Colour Measurements

- Crude Distillation Unit (CDU): Detect crude carryover in the refined product and cuts from the CDU unit

- Diesel Fuel Desulphurization Units: Verifying efficiency of the sulfur removal

- Natural Gas Liquids (NGL): Product quality and colour verification at custody transfer points

- Lube Oil Processing Plants: Product quality and colour verification

- Refined Fuels: Product quality and colour verification after final processing and before the sale

Reliable Saybolt Colour Measurement with Low Maintenance

When accurate, actionable colour data is critical, the Guided Wave Saybolt Colour Analyser is the preferred choice. Its linearity and repeatability, as well as its low maintenance make it a cost-effective, smart choice to help optimise production, improve yields, ensure consistent product quality and enhance profitability.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 22 2024 Hannover, Germany

Apr 22 2024 Marrakech, Morroco

Apr 22 2024 Muscat, Oman

Apr 22 2024 Rotterdam, Netherlands

Apr 23 2024 Singapore