Analytical Instrumentation

How Are Peroxides Analysed?

Jun 20 2021

Analysing the peroxide content of petroleum products is a critical step of the quality assurance process. Defined as any class of chemical compound featuring a pair of oxygen atoms linked by a single covalent bond, peroxides can have a significant impact on the characteristics of fuels, gases and other petroleum-derived products.

So how do buyers and sellers analyse peroxide content? Read on to find out more about the gold-standard techniques used to detect and measure peroxides.

-

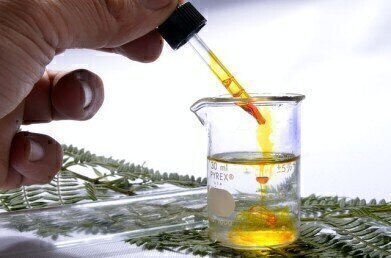

Iodometric titration

Also known as iodometry, iodometric titration is a form of volumetric chemical analysis used to calculate peroxide content based on the presence of elementary iodine. The essential mineral interacts with peroxides to trigger a chemical reaction. This is then used to quantify peroxide content.

-

Flow Injection Analysis

Time and cost efficient, Flow Injection Analysis (FIA) is used at laboratories around the world. The system rapidly injects a petrochemical sample into a continuously flowing reagent stream of acidified iodide. Once injected, the liquid is transferred to a reaction module, where the peroxides react with iodide, change colour and transform into iodine. A UV-VIS detector is then used to measure the intensity of the Iodine and calculate peroxide content.

Why are peroxide assays important?

Peroxide assays are fundamental to quality control and assurance. Failing to accurately calculate peroxide concentrations can jeopardise the performance of a product and cause serious safety concerns. For example, peroxides in butadiene can be extremely dangerous and result in violent explosions. Distilled during the ethylene production process, butadiene is used to manufacture polymers like elastomers and synthetic rubbers. When butadiene reacts with oxygen it forms butadiene polyperoxide, a volatile peroxide that can combust and detonate. The ASTM D5799 – 19 Standard Test Method for Determination of Peroxides in Butadiene was developed to calculate peroxide concentrations ranging from 1 mg/kg to 10 mg/kg.

When found at high concentrations in crude oil containing iron particles, hydrogen peroxide can crack petroleum hydrocarbons. This can affect both the density and viscosity of crude oil, which translates to direct losses of quality and price. Hydrocarbon cracking can also compromise the quality of refined products.

Want to know more about the latest technologies being used to analyse peroxide content of petroleum fuels? Developed by Da Vinci Laboratory Solutions (DVLS), the Fast Peroxide Analyser (FPA) champions a flow injection technique to improve speed, accuracy and safety in the laboratory. Find out more in ‘Fast, Safe and Accurate Analysis of Peroxide Traces in Petrochemicals.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia