-

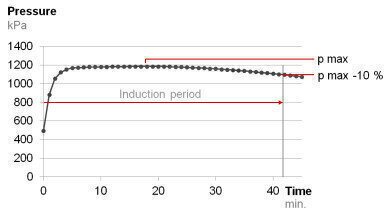

Figure 1: RSSOT / EN 16091 induction period: Time elapsed from starting the heating procedure of the test chamber and a pressure drop of 10 % from the maximum pressure (p max).

Figure 1: RSSOT / EN 16091 induction period: Time elapsed from starting the heating procedure of the test chamber and a pressure drop of 10 % from the maximum pressure (p max). -

Figure 2: RapidOxy 100 Fuel, Anton Paar’s oxidation stability testing solution, is the only RSSOT on the market.

Figure 2: RapidOxy 100 Fuel, Anton Paar’s oxidation stability testing solution, is the only RSSOT on the market.

Analytical Instrumentation

Anton Paar’s ‘Rapid Small-Scale Oxidation’ Method: Quick, Simple, Fully Automatic – Officially Included in EN 590

Aug 16 2022

The RapidOxy 100 Fuel test method EN 16091, which uses the Rapid Small-Scale Oxidation Test (RSSOT), is now officially included in the diesel fuel specification EN 590. With 60 minutes as a limit for the induction period, compared to 20 hours with the alternative method (EN 15751), it is the world’s fastest EN 590 oxidation stability test method.

What Is the Rapid Small-Scale Oxidation Test?

The RSSOT measures the induction period of the complete range of diesel fuels (B0 – B100) in compliance with EN 16091. The test indicates oxidation and storage stability. To release diesel fuel according to EN 590 with EN 16091, a small sample volume of 5 mL is first filled into the RapidOxy 100 Fuel test chamber, and the preset program, “B0 – B100”, is started. The test chamber then automatically charges with oxygen to 700 kPa at ambient temperature. Once this is done, the measurement itself is started by heating the test chamber to 140 °C. The measurement is finished as soon as the break point is reached, which is defined as a pressure drop of 10 % below the maximum pressure of the test run. The result is given as the induction period in minutes: the time elapsed from starting the heating until the break point is reached (Figure 2). The principle is straightforward: The longer the induction period, the more oxidative stable the sample.

Anton Paar’s RapidOxy 100 Fuel

RapidOxy 100 Fuel, Anton Paar’s oxidation stability testing solution, is the only RSSOT on the market. It provides users the fastest release of diesel fuel according to EN 590 in terms of oxidation stability. Highly accurate temperature control and full automation guarantees extraordinary precision, while also delivering excellent reproducibility and repeatability for spark ignition fuels, all kinds of diesel fuels (from B0 to B100), and heating oils according to ASTM D7525, ASTM D7545, and EN 16091. With it, users get high sample throughput, too. The RSSOT is fully automated (the only manual step required is for a user to fill in the 5 mL of diesel fuel sample), which leaves no room for errors. With its built-in safety features (e.g., automatic magnetic lock for the safety hood, over-temperature shut-off, and over-pressure shut-off) and compact benchtop size, the instrument is perfectly suited for oxidation stability testing of fuels. Using it is easy: Measurement setup takes less than five minutes, the test chamber can simply be wipe-cleaned, and the compact, stand-alone design takes functionality to another level.

Digital Edition

PIN 25.2 Apr/May

April 2024

In this Edition Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector...

View all digital editions

Events

May 06 2024 Riyadh, Saudi Arabia

May 06 2024 Houston, Tx, USA

May 06 2024 Houston, Tx, USA

Canada Gas & LNG Exhibition & Conference

May 07 2024 Vancouver, BC, Canada

May 08 2024 Lahore, Pakistan