Measurement and Testing

Wireless solution for the industrial IoT, adds value in plant maintenance.

Feb 11 2019

Yokogawa Electric Corporation has announced that it will release the Sushi Sensor, an OpreXTM brand wireless solution, in markets other than Japan, starting with Europe (shipping in March 2019). Already available in Japan, the Sushi Sensor is a compact wireless device with integrated sensing and communication functions that is intended for use in the monitoring of plant equipment vibration and surface temperature. Optimised for industrial IoT (IIoT) applications, the Sushi Sensor enables the online monitoring of equipment operating conditions, which helps to improve equipment maintenance and prevent failures by detecting signs of abnormalities at an early stage.

As manufacturers strive to improve productivity and the efficiency of their plant maintenance operations, they have a growing need for solutions that facilitate the collection of equipment data. This is driving demand for wireless sensors that are easier and cheaper to install than conventional wired devices.

To detect signs of equipment abnormalities at an early stage and prevent unexpected equipment failures, it is essential to frequently measure the vibration and surface temperature of plant equipment such as compressors, pumps and motors, and to enable the monitoring of such data online. Although crucial equipment may already be continuously monitored by using wired sensors, this may be difficult with many other types of equipment due to the high initial cost and the challenges of wiring devices in difficult to access locations. Such equipment must be inspected during operator rounds or periodic inspections. Therefore, there is an increasing need for wireless vibration and temperature sensors that can be installed easily and at a low cost, to improve maintenance efficiency.

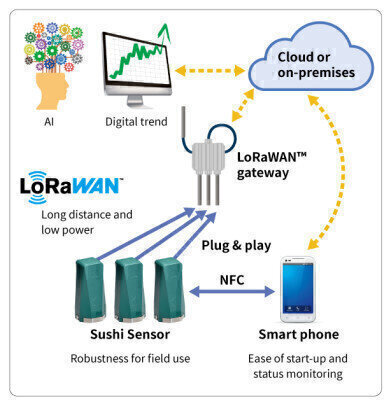

To meet this need, Yokogawa has developed the Sushi Sensor, a compact wireless device that measures vibration and temperature and uses LoRaWANTM, a low-power wide-area (LPWA) wireless data communication protocol that is attracting considerable interest among developers for use in IIoT applications. LPWA is a wireless communications technology which is optimised for long-distance communications and low-power consumption. LoRaWAN, an LPWA protocol that is based on an open standard, is promoted by the LoRa Alliance of more than 500 IoT companies and users worldwide.

Yokogawa released the Sushi Sensor in the Japan market in March 2018, and has already established a solid track record with the device. Yokogawa also offers field wireless systems that comply with the proven and highly reliable ISA100 WirelessTM standard and help to ensure stable and safe plant operations. This wireless networking technology based on the ISA100.11a wireless communication standard for industrial automation that was developed by the International Society of Automation (ISA).

The European release of the Sushi Sensor is set for 2019, with other regions following after that, giving its customers in various markets a greater range of optimum solutions to choose from.

The compact wireless sensor complies with the LoRaWAN communication standard for long-distance communications, and thus needs no repeaters. It is also battery-powered, eliminating the need for an external power supply. Being compact and light-weight, this sensor can be mounted easily on all kinds of plant equipment. In addition, the sensor supports near-field radio communication (NFC), which allows sensor setting and sensor condition monitoring from a smartphone via a dedicated app. This technology is suitable for short-range communications, over a distance of several centimeters, enabling quick data exchange.

Although vibration sensors and temperature sensors for IoT applications are commercially available, most of them were designed for indoor use. Yokogawa’s compact wireless Sushi Sensor is environmentally robust and is well suited for installation in harsh plant locations.

Data collected by the Sushi Sensor can be monitored either from an on-premise server or a cloud server via a LoRaWAN gateway. From the on-premise server or any device in a remote location that can access the cloud server, operators and maintenance staff can monitor the vibration and surface temperature of equipment throughout a plant.

For the monitoring of equipment operating conditions, the compact wireless sensor with integrated sensing and communication functions collects vibration and surface temperature data and transmits this data to an on-premise or cloud server via a LoRaWAN gateway.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia