-

The blue bridge in Dresden, Blaues Wunder

The blue bridge in Dresden, Blaues Wunder -

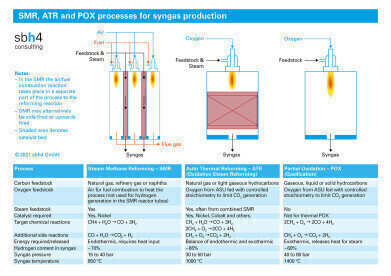

SMR ATR and POX processes

SMR ATR and POX processes

Fuel for Thought

The blue bridge - Integrated reforming and carbon capture to make blue hydrogen

Feb 15 2021

Author credit – Stephen B. Harrison, sbh4 consulting

In the 1890s a famous blue bridge was built across the river Elbe at Dresden in Germany. One hundred and thirty years later, the phrase ‘blue bridge’ has returned to the headlines.

On the 27th of January 2021, the European Parliament voted that blue hydrogen produced on reformers from natural gas with carbon capture will be an acceptable ‘blue bridge’ on the journey to full decarbonisation with green hydrogen. This must be one of the most important hydrogen policy decisions that has been taken recently.

Steam methane reformers consume natural gas to make hydrogen. The vast majority make grey hydrogen and emit carbon dioxide. In the long term, this can be mitigated with ‘green’ hydrogen production using electrolysers fed with renewable electricity or reformers fed with biogas. In the short-term retrofitting carbon capture to steam methane reformers (SMR) and autothermal reformers (ATR) to make so-called ‘blue hydrogen’ will make a big difference.

The blue hydrogen paradigm shift

SMRs have benefited from 4 decades of optimisation. ATRs are newer but have also had more than a decade of operation to allow fine tuning. In some cases, SMRs and ATRs are operated in series in a process called ‘combined reforming’ or ‘two stage reforming’.

The components of a CCS scheme, from the absorption tower to the multi-stage CO2 compressor with integrated drying system are highly developed. CCS has been used at scale in Australia, Canada, Norway, and the United States for many years. CCS is also an established technology, but most major CCS schemes implemented up to now have been retrofits onto carbon-intensive processes.

Reforming and CCS technologies have been optimised in parallel. The processes have never been optimised holistically. For new schemes, a paradigm shift is required: blue hydrogen production must be optimised as an integrated, synergistic process.

Use cases guide the hydrogen production process

Selection of the appropriate hydrogen production technology will, in part, come from a detailed understanding of the energy and chemical feedstocks required from the scheme. SMRs can be optimised to produce hydrogen. ATRs can be optimised to produce syngas which is a mixture of hydrogen and carbon monoxide. For decarbonisation of the natural gas grid for domestic heating and cooking applications, hydrogen is the target molecule. That favours the SMR.

Some of chemicals plants require carbon monoxide as a building block to synthesise complex molecules. Syngas can also be burned on electrical power plant gas turbines. The choice of SMR, ATR or combined reforming will partly be driven by the mix of gases required close to the blue hydrogen production scheme.

Pressure for the pipeline

Operating pressure, and therefore product gas delivery pressure is another aspect that differentiates SMRs and ATRs. The ATR can operate at a higher pressure. This is a benefit if hydrogen must be injected into a high-pressure gas pipeline for long distance transmission.

Within the CCS scheme, carbon dioxide must be pressurised to around 200 bar for injection underground. If the CO2 from the carbon capture system on the ATR or SMR is produced at high pressure, the energy requirements to compress the CO2 to the target 200 bar can be reduced. Again, high-pressure operation would be favoured.

Value stacking and process optimisation

SMRs do not require pure oxygen. On the other hand, ATRs do. This means an air separation unit must be built if the ATR technology is used. Downstream of the reformer, there may also be a blue ammonia plant to increase the value of the overall scheme. This would require nitrogen as a chemical feedstock to react with the hydrogen to make ammonia which can be liquefied as an export product, leveraging existing international ammonia supply chains.

The nitrogen would be produced on the ASU alongside the oxygen. It is impossible to say whether the nitrogen or the oxygen is the product or the by-product. The processes are integrated and interdependent – ‘value stacking’ often ends up looking more like a virtuous circle than a linear stack.

Integrated process optimisation of the scheme to produce hydrogen, syngas and ammonia, combined with the associated air separation and CCS will be a highly complex process. Optimising blue hydrogen production requires a paragim shift to focus on the holistic system and move beyond individual unit operations or retrofit solutions.

Digital Edition

PIN 25.2 Apr/May

April 2024

In this Edition Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector...

View all digital editions

Events

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia

May 06 2024 Houston, Tx, USA

May 06 2024 Houston, Tx, USA