Analytical Instrumentation

Yokogawa releases Enterprise Pipeline Management Solution

Oct 21 2015

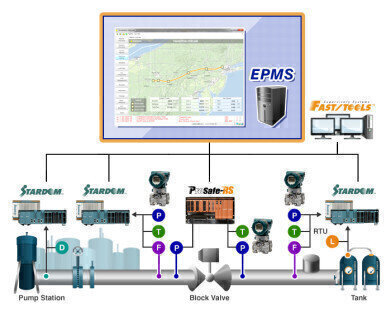

The Yokogawa Enterprise Pipeline Management Solution (EPMS) is a modular software suite that is the product of over 20 years of practical experience in implementing pipeline management solutions across the globe.

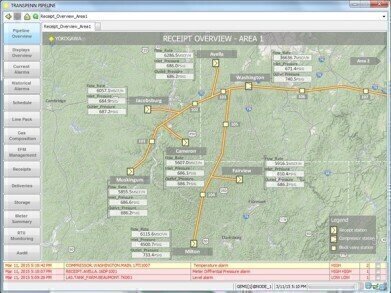

Developed for deployment at the heart of the pipeline operations management environment, the EPMS supplements the basic pipeline management system with specific gas and liquid applications that enable a pipeline operator to manage delivery contracts and associated logistics in a time and energy-efficient manner. With a SCADA platform covering monitoring, alarming, trending and reporting, the EPMS handles functions such as metering, batch scheduling and tracking, leak detection and energy management within the same unified user environment.

Key benefits of the new system include:

- Unified user environment based on a modular design: Based on a well-designed modular platform that is both IT friendly and secure, the EPMS is a sustainable solution that can deliver pipeline applications in combination with common supervisory and monitoring functions. As no two pipeline applications are identical and operational philosophies can differ from one pipeline operator to the next, the EPMS’s templates and functions can be easily modified without having to call in pipeline application experts.

- Contextual online integrity management: The EPMS features improved alarm and human-machine interface (HMI) management functions, with both it and its application platform based on standards put forward by the American Petroleum Institute (API) and the International Society of Automation (ISA) and complying with the strict regulations of the US Department of Transportation’s Pipeline & Hazardous Materials Safety Administration (PHMSA). The EPMS employs leak detection, compensated volume balancing, and hydraulic profiling methodologies to monitor pipeline integrity under every type of operating condition. The EPMS is thus able to register possible integrity violations together with contextual information about the operational state of the pipeline so that personnel can quickly get to the bottom of any problem.

- Reduced energy consumption: The EPMS continuously makes adjustments to the setpoint so that both compressors and pumps can be operated as close as possible to the optimal efficiency point. To manage exceptions during startup, the EPMS allows the assignment of business rules for the management of load sharing, compressor/pump restrictions, and alarm notifications at the compressor/pump station level. To identify areas for improvement, the EPMS can also record all key power statistics.

- Less product waste at batch delivery points: To minimise product waste, the EPMS measures and calculates the position of batches as well as anomalies such as trans-mix on a near real-time basis, and reports on the inventory balances.

- Enhanced gas and liquid metering: With its transparent management of parameter exchange and the measurement of gas, liquids and gas composition, the EPMS easily adapts to the desired measurement methodology and the level of intelligence of intermediate devices like flow computers, remote terminal units (RTUs) and instruments. It processes the available inputs into normalised flow, volume and energy values in accordance with the applicable American Gas Association (AGA) and API standards.

For further information and references and success stories please click here.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia