Analytical Instrumentation

Extensional Properties of Fluids can now be Quantified Using Normal Force Measurement

Jun 08 2009

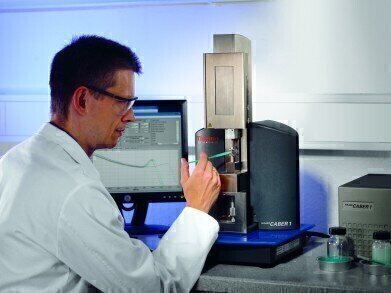

Thermo Fisher Scientific Inc. (USA) announce that it has expanded measurement options on its Thermo Scientific HAAKE CaBER extensional rheometer. With the only commercially available extensional rheometer, the company now makes it possible to quantify the extensional properties of fluids using normal force measurement. These options were developed in cooperation with the workgroup of Prof. Dr. Manfred Wilhelm, Karlsruhe Institute of Technology. Rüdiger Brummer, of Beiersdorf in Hamburg, provided application engineering support to the project.

The measuring principle of the easy-to-use, software-controlled extensional rheometer involves placing a sample between two plates and moving the upper plate upwards at very high speed in order to produce a fluid filament. A laser micrometer is used to determine the decrease in filament diameter as a function of time. Physical effects such as surface tension, elasticity, viscosity and mass transfer determine the extensional flow and can be quantified using model fitting analysis. In this way, important insights can be gained for such processes as fluid filling behavior, the hardening of adhesives or the spray behavior and misting of printing inks and wall paints. The measuring principle is ideally suited for viscoelastic samples which form cylindrical filaments on extension, such as cosmetic emulsions, hair colors, printer inks, food products, or certain adhesives.

The expanded measuring concept now also permits the measurement of samples with non-cylindrical filament formation and is based on a highly sensitive, fast, normal force measurement in the sub-milli-Newton range which is integrated in the lower measuring geometry of the instrument and combined with modern data-recording technology. The normal force which acts on the lower plate is determined while the upper plate is already moving upwards. In this way, information regarding filament formation and extensional properties is determined, which is not available from the classic HAAKE CaBER experiment.

“In the interest of protecting our customers’ investments, we are selling new instruments with this new measurement option,” says Markus Schreyer, vice president and general manager of Thermo Fisher Scientific’s material characterization business unit. “And we are also making sure that existing HAAKE CaBER test assemblies can be expanded to add this measuring principle.”

Thermo Fisher Scientific successfully supports a wide range of industries with its comprehensive Thermo Scientific material characterization solutions. These products analyze and measure viscosity, elasticity, processability and temperature-related mechanical changes of plastics, food, cosmetics, pharmaceuticals and inks, coatings, or petrochemical products.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia