Analytical Instrumentation

Sulphur analysis

Mar 18 2011

One of the major considerations in the cost control process is how much treatment each barrel of crude oil will need to reduce the naturally occurring sulphur to operational levels that will make a product that meets federally mandated standards for sulfur content. Part of the required testing consideration to keep products in specification with the mandated sulphur levels is the overall cost of ownership of testing and measurement equipment for refiners, pipeline operators and product distributors. This cost includes capital expenditure, operating costs and life expectancy.

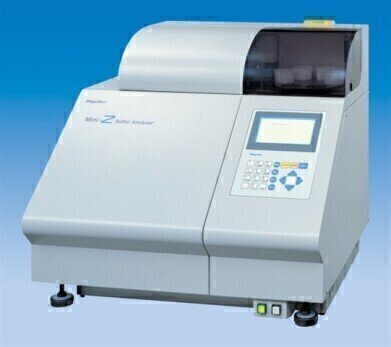

The Micro-Z sulfur from Rigaku (USA) is designed first and foremost to meet performance requirements of the industry, so this benchtop WDXRF analyser has the capability of measuring both the sulphur peak and associated background for every analysis as specified in ASTM 2622-08. The instrument has been designed to take advantage of industry-leading optics, using curved crystals to improve X-ray intensity captured by the sealed proportional detector, allowing unparalleled sensitivity and meeting industry mandated detection limits. The close-coupled geometry of the excitation source and sample allows for the use of low-powered X-ray tubes. This excitation system, while still producing high intensity X-ray fluorescence from samples containing sulphur in low concentration levels, has no need for external cooling chillers.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia

May 06 2024 Houston, Tx, USA