Analytical Instrumentation

Analysis of Metals in Crude and Residual Oil, as per ASTM D8252Model: Rigaku NEX QC+

Nov 20 2019

Scope

The analysis of nickel, vanadium and iron in crude and residual oil as per ASTM D8252 is demonstrated. The measurement also includes the analysis of sulfur complying with ASTM D4294.

Background

The quality and grade of crude oil in part depends on the metal content as well as the sulfur content. Nickel and vanadium are the critical metals, as well as iron in some crudes and in residual oils and the metal content is especially important in the quality of bunker fuels.

ASTM D8252 addresses the need to measure low levels of nickel and vanadium in crude to meet the new NYMEX/CME specifications for light sweet crude oil futures contract concerning maximum allowable levels the Ni and V.

To meet the needs of the industry, Rigaku offers the NEX QC+ analyzer - a simple, versatile, and portable benchtop EDXRF spectrometer for the analysis of sulfur in crude, residual oil and marine fuels.

Instrumentation

Model: Rigaku NEX QC+

X-ray tube: 4 W Ag-anode

Detector: SDD

Sample Type: Crude and Residual Oil

Film: Mylar

Analysis Time: 360 sec

Environment: Air

Sample Preparation

To measure a sample, gently shake the sample bottle, allow bubbles to settle and fill a 32mm XRF sample cup 3/4 full (approximately 5g).

Calibration

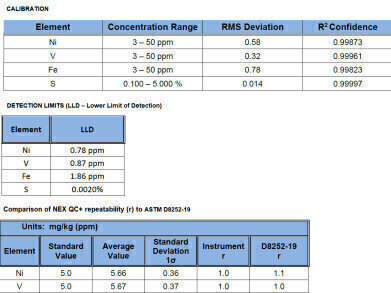

Empirical calibrations were built using a suite of 12 commercially available calibration standards. A summary of the empirical calibrations is shown here.

See TABLE (Calibration)

Repeatability (Precision)

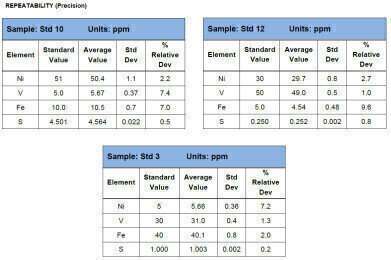

To demonstrate repeatability, samples was measured in static position for ten repeat analyses using a total analysis time of 360 sec per measurement, with typical results shown below.

See REPEATABILITY TABLE

Detection Limits (LLD – Lower Limit of Detection)

The empirical method is used to determine detection limits using 360 sec measurement time. Ten repeat analyses of a blank mineral sample are taken with the sample in static position and the standard deviation (σ) is determined. The Lower Limit of Detection (LLD) is then defined as three times the standard deviation (3σ).

See TABLE (Detection Limits)

ASTM D8252-19

In ASTM, “r” indicates repeatability and represents the precision of the measurement. “r” is 2.77 times the 1σ standard deviation precision of repeat measurements. Comparison of the NEX QC+ instrument r to the method r of D5282 shows NEX QC+ analyzer complies with the ASTM method for the measurement of Ni and V in crude and residual oil.

See TABLE (Repeatability)

Conclusion

The performance shown here demonstrates the ability of the NEX QC+ analyzer for the measurement of metals in crude and residual oil as per ASTM D8252 and sulfur in compliance with D4294. The simple user interface and low maintenance requirements of the NEX QC+ system allows operators of all skill levels to use and maintain the equipment.

Digital Edition

PIN 25.2 Apr/May

April 2024

In this Edition Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector...

View all digital editions

Events

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia

May 06 2024 Houston, Tx, USA

May 06 2024 Houston, Tx, USA