Analytical Instrumentation

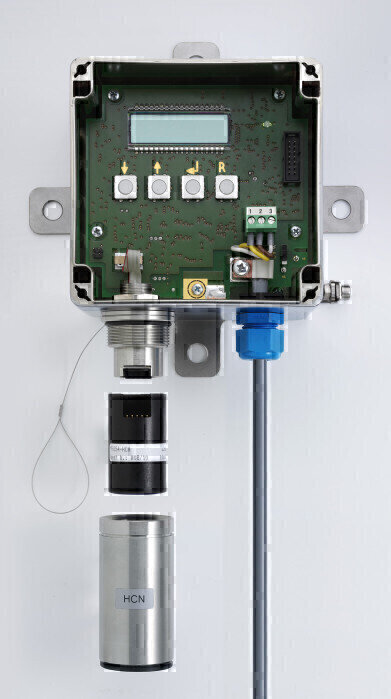

Gas Detection System Compur Statox 505 with SIL 2 Standard will always let you know what is going on in your Plant

Dec 15 2010

The Statox 505 is a 4 – 20 mA Transmitter for toxic gases and oxygen by Compur Monitors (Germany). It features everything that a gas detection instrument of the new generation needs. It includes state of the Art components (hardware and software), smart sensor technology, “heartbeat” sensor control and complete system diagnostics.

In process monitoring, the status information of plant components, in case of a failure, is becoming more of a critical issue. The standards DIN EN 61508 as well as the product standard DIN EN 50402 are powerful tools to calculate the probability of a failure on demand. The Statox 505 complies with all of the requirements of these standards. It complies with safety integrity level SIL 2 requirements of DIN EN 50402 based on a 6 month proof test interval. Or with SIL 1 requirements of DIN EN 61508 based on a one year proof test interval. This provides a reliable database for the user to calculate the safety standard of his plant.

All important parameters such as sensor “heartbeat“, signal output, calibration, sensitivity, temperature, sensor memory, amplifier, CPU, power supply are continuously monitored for proper function. In addition, it checks for a negative zero. In case of a failure, an alarm will be triggered; thus, the system cannot fail without the error being noticed. A green LED shows the system status. The display and the controls are located at the inside of the housing and are well protected from the elements.

The sensors of the Statox 505 are plug and play technology. Each sensor has an F- RAM on board which communicates all relevant parameters to the sensor head; including gas, measuring range, last calibration, ex works calibration, response time, alarm events etc.

The sensors can easily be calibrated in the shop. Therefore, calibration work will never be required within harsh elements (wind, rain, cold, heat). In addition, carrying heavy test equipment and gas cylinders into the field will not be necessary. Quite simply, all the user has to in the field is plug the sensor back in. While the sensor is being calibrated in the shop, the sensor cartridge remains in place and protects the sensor head from both dust and rain.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia