Flow Level Pressure

Small Sample Viscometers Key to Accurate Viscosity Analysis

Aug 15 2011

What do you do if you need accurate viscosity information, but have only a small sample of material available to test? Small sample viscometers are helping researchers, analysts and technicians address this need across a broad array of applications.

Cambridge Viscosity (USA) viscometers reduce the amount of laboratory sample test material required, which can be very costly, or in some cases, available only in limited quantities. Accurate small sample viscosity information is required in oil and gas exploration, refining, oil analysis, life sciences, coatings and many other applications. In processes that require precise in-process measurements that correlate directly with laboratory measurements, Cambridge’s oscillating piston technology readily achieves this standard.

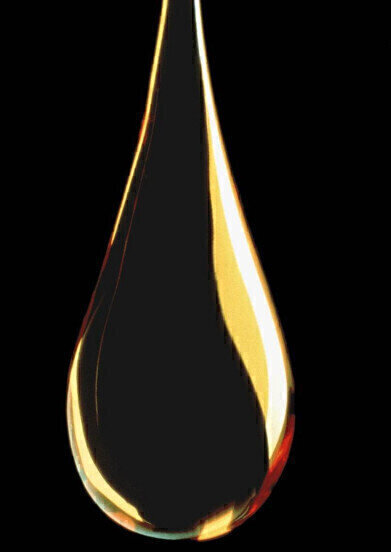

Oil reservoir production is driven by four factors: the viscosity of the fluid in the earth, the porosity and permeability of the rocks through which it will be extracted, and the pressure effects on the reservoir fluid. Oil companies determine these by drilling an exploratory well, taking rock and fluid samples perhaps a mile under the earth, and analysing the samples under laboratory conditions. Working with the world’s largest oil companies, Cambridge has become the “gold standard” for reservoir oil analysis, adapting their viscometers to provide accurate and reliable measurements with small amounts of fluid in high pressure/high temperature conditions.

Many refinery products are produced and sold based upon their viscosity. Refiners maximise quality throughput by combining required internationally accepted laboratory tests with in-line viscosity measurements to control product viscosity real-time. The in-line measurement must be validated with a refiner’s standard laboratory test results. This is a high stakes proposition for refiners: substantial off-quality can be produced if the measurements are incorrect. Highly accurate results require minimal variations in sample conditions between in-process and laboratory measurements. Cambridge sensors require very small sample for measurements, which enables refiners to condition a small sample stream rather than an entire refinery process to achieve a high degree of accuracy.

Viscosity is the most important lubrication specification, and is a key indicator of equipment health, so oil analysis is performed both in laboratories and in in-service conditions. In-service challenges for oil analysis include space limitations for instrument, high levels of repeatability, high vibrations and flow fluctuations and a wide range of temperatures and pressures. In applications ranging from compressors to engines, sub-optimal lubricant viscosity leads to excessive bearing wear and failure of rotating parts. Measurements must be made in process conditions that require small, accurate and robust viscometers that are compact enough to be inserted into extremely small spaces. With the smallest in-line process viscometers available, Cambridge viscometers are widely used in established to emerging applications and economies.

There are a wide variety of performance coating applications, ranging from optical and medical devices to beverage cans, fine wire and printer drums. All require precise and uniform film thickness to achieve product performance requirements. This film thickness is most accurately managed in-process through precise control of the film coat viscosity. Cambridge viscometers are ideal for monitoring performance coating viscosity as they utilise compact sensors that easily fit into existing installations, incorporate temperature-compensated viscosity to mathematically adjust readings for temperature changes, and are certified for use in hazardous environments.

Digital Edition

PIN 25.2 Apr/May

April 2024

In this Edition Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector...

View all digital editions

Events

May 06 2024 Riyadh, Saudi Arabia

May 06 2024 Houston, Tx, USA

May 06 2024 Houston, Tx, USA

Canada Gas & LNG Exhibition & Conference

May 07 2024 Vancouver, BC, Canada

May 08 2024 Lahore, Pakistan