-

-

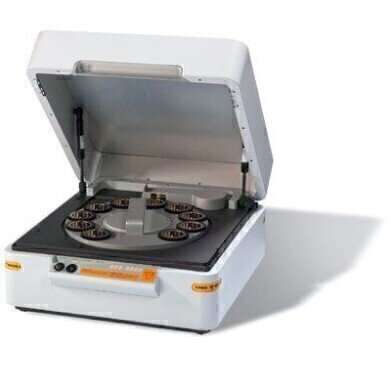

Epsilon 3XLE

Epsilon 3XLE

Analytical Instrumentation

Reduce refinery corrosion by easy chlorine analysis in crude oil & distillates

Mar 16 2016

Reducing downtime of the refining operation, for instance by corrosion prevention, improves your margins significantly. About one third of maintenance downtime can be linked to corrosion. Chlorine content in crude oil and process streams is responsible for an important part of the corrosion. The Total Acid Number (TAN) of oils and fuels is an important parameter in managing corrosion caused in the refinery. Chlorine and sulfur content next to the naphthenic acids, contribute to the TAN and are unwanted elements in crude oil and other petrochemical products. Next to the corrosion they cause in the oil-processing and refinement installations they are also harmful for the environment.

X-ray fluorescence (XRF) is widely used for the analysis of sulfur in oil. However, the simultaneous determination of very low chlorine concentrations poses an analytical challenge due to the proximity of both elements in the periodic table of elements. PANalytical’s Epsilon 3XLE energy dispersive X-ray fluorescence spectrometer is perfectly able to meet this challenge. The combination of market leading hardware features and the powerful software enables the system to process high sulfur count rates and at the same time resolves possible line overlaps between chlorine and sulfur.

“The lower limit of quantification for chlorine in the presence of percentage levels of sulfur is below 2 mg/kg (ppm), which makes the Epsilon 3XLE the perfect solution for this challenging task,” says Taco van der Maten, petro segment marketing manager. “Furthermore, the system caters for variable characteristics of crude oil composition thereby enabling a more robust and accurate determination of chlorine. The possibility to analyse all other relevant elements from Na to Am with similar outstanding accuracy and repeatability, makes it a valuable asset for a wide range of petrochemical applications”.

Visit the website to find out all the details.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia