Analytical Instrumentation

Cost-effective method to comply with the new industry standard IP600 to determine low sulphur concentration in automotive fuel

Mar 20 2013

Wherever sulphur analysis is required to meet international test methods such as IP600, ASTM D4294 and ISO13032, Oxford Instruments provides field proven, compact, cost-effective X-ray fluorescence (XRF) analysers.

Quality control laboratories in refineries and testing houses have long used Energy-Dispersive X-ray fluorescence (EDXRF) spectrometers, e.g. Oxford Instruments Lab-X and X-Supreme to analyse fuels. The excellent performance, versatility, ease of use, speed, and cost-effectiveness of this technique make the EDXRF spectrometer the analytical tool of choice for fuel analysis, from the lower detection limits to high concentration levels to comply with industry standards.

For example, automotive fuels follow stringent regulations and many countries already produce, or are scheduled to produce, ultra-low sulphur (< 10 or 15 mg.kg-1 sulphur) automotive fuels. The recently introduced IP600 and ISO13032 cover a range of automotive fuels including standard diesel and those containing up to 10% fatty acid methylester (FAME). It also includes automotive gasoline containing up to 3.7% oxygen, and gasoline blended with ethanol up to 10%, measured using the analytical technique of high performance Energy dispersive X-ray fluorescence.

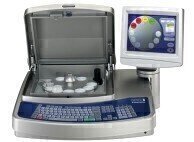

Oxford Instruments offers a high performance, field proven EDXRF spectrometer, the X-Supreme8000 that successfully performs the required sulphur analysis in automotive fuels to comply with ISO13032.

Additionally, the X-Supreme8000 allows sulphur analysis from a few parts per million (ppm) to 5% in all fuel types plus the ability to measure other elements such as Cl in oil Ni, V in fuel oil and Pb in gasoline etc. and thus complies with IP600, ASTM D4294, ISO20847 and ISO8754.

It comes with an integrated 10 position sample carousel for minimum bench space and unattended operation, often used on a 24/7 basis by shift personnel allowing confirmation of product specification. The rugged and robust design is ideal for harsh environments; its sealed membrane keypad is resistant to dust, oils, solvents etc. The X-Supreme8000 comes with a secondary easy-to-change safety window. This window protects the instruments for liquids/power analysis in the event of sample leakage, providing trusted, successful analysis, year after year.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia

May 06 2024 Houston, Tx, USA