-

-

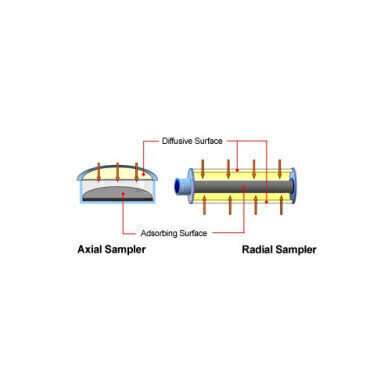

sampler (Figure 1)

sampler (Figure 1)

Analytical Instrumentation

High performance passive petrochemical air monitoring using radial sampling

Sep 17 2019

The inherent speed and consistency limitations of axial air sampling have been by-passed by use of 360° radial samplers. A product of government/industry collaboration, the innovative radiello™ passive air samplers provide rapid, reliable, and sensitive results trusted by the petrochemical industry.

The petrochemical industry requires a variety of air monitoring devices to measure emissions from manufacturing operations and to assess employee exposure risk to hazardous chemicals such as benzene, toluene, ethylbenzene, xylene (BTEX) and volatile organic compounds (VOCs); hydrogen sulfide, nitrogen dioxide and sulfur dioxide. It is known that benzene is a highly carcinogenic gas and hydrogen sulfide is a strong chemical asphyxiant.

Employees who work in this industry are at risk of exposure to chemical compounds that are detrimental to health and safety. Communities may also assume similar risks at times of environmental crisis such as oil spills1 , or fugitive emissions from the wide range of petrochemical operations and transportation processes. We offer the proven radiello™ passive air sampler, with its innovative radial design, for accurate measurement of low levels of these contaminants.

Radiello™ passive air samplers for trusted results

Radiello™ passive air samplers consist of a radial diffusive body made of porous polypropylene in which a cartridge with adsorbent is positioned. The adsorbent bed is selected for application and can consist of a pure adsorbent material or a chemically coated support. Due to this symmetry analytes can access the adsorbent material throughout the 360° surrounding diffusive barrier/body resulting in a significant higher uptake rate. By virtue of radial symmetry, the uptake rates with the same dimensions, radiello's are at least three times higher than for any axial diffusive

Figure 1. Uptake/Sampling rates are higher for radial samplers than axial (e.g. Benzene @25°C <10 mL/min vs. >70 mL/min).

Due to the tortuous nature of the diffusive path inside the micro-porous diffusive membrane, the uptake rate is not affected by wind or air currents. The stiffness of the diffusive wall and cartridge, together with the close tolerances characterising all the radiello components, greatly reduces uptake rate variation. The uptake rates are experimentally measured in a controlled atmosphere chamber over a wide range of concentration, temperature, relative humidity, air speed, with and without interferences. The cartridge adsorbents provide high capacity and minimal reverse diffusion.

Features and Benefits

- No sampling pump required

- Low detection limits, high uptake rates and high capacity allows for sampling time ranges from 15 min. to 30 days (1 ppb–1000 ppm)

- Greater adsorbent capacity offers minimal reverse diffusion and greater uptake rate consistency resulting in more reproducible results

- Radial design gives high and consistent sampling rates

- Proven performance for sampling in petrochemical environments2

- Trial size radiello™ starter kits available

For further information please click here.

References

Center for Toxicology and Environmental Health (CTEH): MC 252 Oil Spill Air Sampling and Analysis Plan, May 2010

Nicholas P. Cheremisinoff, Anton Davletshin, Emergency Response Management of Offshore Oil Spills: Guidelines for Emergency Responders, John Wiley & Sons, 2010

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia

May 06 2024 Houston, Tx, USA