Analytical Instrumentation

The Elemental Analysis of Lubricants

Apr 20 2016

A lubricant is a substance introduced to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. Typically lubricants are composed of 90% base oil (most often petroleum fractions called mineral oils) and 10% additives. The additives are present to impart desired performance characteristics to the lubricant. The properties include oxidation inhalation, detergency, corrosion inhalation and friction modification, along with many others. Proper control of the concentration of these additives is critical to the control of these performance characteristics.

These additives include compounds of barium, calcium, phosphorus, sulfur and zinc. The concentrations are typically in the mass % range from 0.01-8.50. The rapid and reliable determination of these levels is important to assess the usability of the lubricant for specific applications. At these concentrations, there are a variety of analytical techniques which could be employed, but X-ray fluorescence is one which has gained popularity over the years. The speed (<5 minutes per analysis), cost (<$1.50 per analysis) and lack of additional utility requirements (no gases required) have made this an attractive alternative.

A newer manifestation of this technology is the X-5000 from HORIBA. This is an energy dispersive X-ray fluorescence system (EDXRF), which complies with ASTM D7751-1401 for exactly this determination. This method focuses on the metals such as calcium, magnesium, molybdenum and zinc; but also does inorganic elements, such as chlorine, sulfur and phosphorus. The pooled limit of quantitation of this method is below the typical levels found in lubricants, so the method is fit for use.

The X-5000 performs this analysis quite easily and is very intuitive for the operator to use. Following proper calibration with HORIBA provided standards; it becomes a simple, one-button operation for the user. Its compact size and its requirement only for clean power make it easy to use in any laboratory. The inexpensive purchase price and low cost of ownership makes it ideal for routine analysis in laboratory releasing the lubricant to market. It can perform the same analyses, which more expensive EDXRF or Inductively Coupled Plasma (ICP) units at a fraction of the cost.

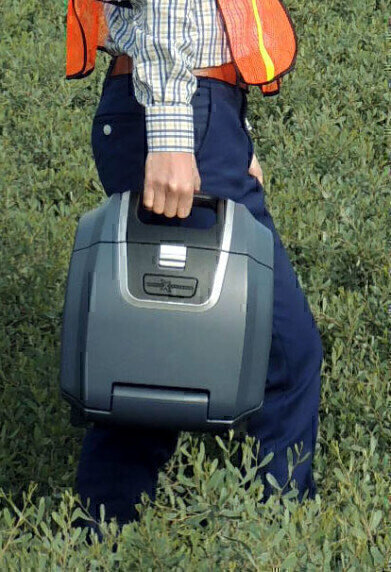

As an added benefit, the unit can be operated from a battery pack enabling it to be carried into the field. Its handle and light weight make it easy to transport in a pick-up truck. This makes it an excellent tool to monitor the history of lubricating oil as it is actually being used in the field. This rugged, versatile instrument finds uses throughout the product life of the lubricant. The detection of one out of limits oil sample will pay for the instrument many times over. For more information, contact Allen Bickel at 949-463-4945 or visit the website.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia