-

XDS Rapid Liquid Analyzer

XDS Rapid Liquid Analyzer -

XDS Process Analytics

XDS Process Analytics -

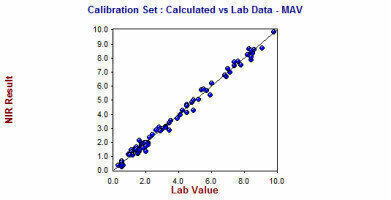

Figure 1 - Calibration results for MAV in Pygas

Figure 1 - Calibration results for MAV in Pygas -

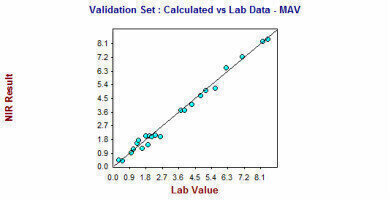

Figure 2 - Validation results for MAV in Pygas

Figure 2 - Validation results for MAV in Pygas

Analytical Instrumentation

Measurement of Maleic Anhydride Value (MAV) with FOSS NIRSystems XDS - for the determination of low levels of conjugated Diolefins in Pyrolysis Gasoline

Jul 21 2010

FOSS NIRSystems lab and on-line analysers have been performing Near-Infrared (NIR) analyses of a variety of Petrochemicals including gasoline, diesel, and crude oil since the late 1980’s. Often these have been measurements of components in the percentage range, which tend to be much easier than components at lower levels.

One NIR method, below the percentage range, that has been successfully developed using FOSS NIRSystems XDS analysers is that of Maleic Anhydride Value (MAV) in Pyrolysis Gasoline (Pygas). Pygas is a by-product of ethylene production, which has some unwanted conjugated diolefins present that make them unsuitable as a motor fuel. Pygas is treated in a Selective Hydrogenation Unit (SHU) to reduce these conjugated diolefins to below 2mg/g (0.2%), so it can be used in gasoline production. The conjugated diolefins are measured using the Diels-Alder wet chemical method for MAV, which is indicative of the amount of conjugated diolefins present. This wet chemical method requires several hours to perform and highly trained analysts. The NIR method described below is very fast – a few minutes – and can be performed by relatively unskilled operators.

Figure 1 shows the PLS calibration results for MAV, using 97 samples collected over time to represent a range of MAV results, variation in the process, and variation in the feedstock used for ethylene production. The results compare very well to the lab analysis, with accuracy (Standard Error of Calibration, SEC) of 0.24mg/g. A further 27 samples were subsequently collected over a period of several weeks. The calibration model was used to predict their MAV value, which is compared to the lab analysis in Figure 2. The prediction error (Standard Error of Prediction, SEP) of 0.25mg/g compares well with the calibration error. The validation samples were collected during several changes in the feedstock to the ethylene process, indicating that the calibration works well for the different conditions expected from the process over time.

The NIR analysis of MAV in Pygas has been considered complicated due to the presence of other non-conjugated dienes, as well as alkenes that have similar molecular functional groups. In addition, the bulk of the samples are a complicated mixture of aromatics and alkanes, which vary with process conditions in the ethylene production, as well as the different feedstock used to produce ethylene (which can be alkanes, naphtha, or gas oil). Also, the MAV is not due to one specific conjugated diolefin, but over a dozen different compounds including cyclopentadiene (a ring structure) and straight-chain diolefins with different chain lengths and side chains. The NIR analysis in such a complicated system is successful through a combination of stable NIR measurements with the FOSS XDS analyser, and the Partial Least-Squares (PLS) modelling capabilities in the VisionTM software.

The NIR results are obtained very rapidly, with no sample preparation besides the temperature equilibration of the sample prior to scanning. This makes it possible to monitor and control the process, which was not possible using other methods. The NIR measurement does not require a highly trained analyst – disposable HPLC vials are the only thing needed for the analysis!

While these results are for the lab analysis of grab samples, there is no reason why this could not have been done on-line, in the outlet Pygas stream from the SHU using a NIR process system. This would allow direct feedback control of the process and further reduce variation in the Pyrolysis Gasoline.

The combined capability of the FOSS NIRSystems hardware and software makes it possible to monitor MAV of Pygas easily, conveniently, and accurately in a matter of a few minutes.

Please Contact Us for more information!

Digital Edition

PIN 25.2 Apr/May

April 2024

In this Edition Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector...

View all digital editions

Events

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia

May 06 2024 Houston, Tx, USA

May 06 2024 Houston, Tx, USA

Canada Gas & LNG Exhibition & Conference

May 07 2024 Vancouver, BC, Canada