Analytical Instrumentation

New Energy Dispersive X-Ray Fluorescence Spectrometer

Aug 16 2011

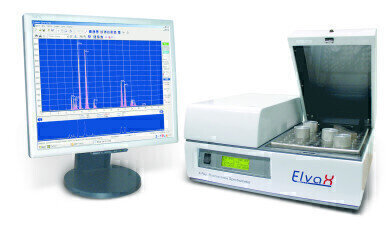

Elvatech Ltd. (Ukraine) introduce ElvaX Light SDD, the new version of Elvax Light Energy Dispersive XRF spectrometer. This compact instrument is used where precise qualitative and quantitative analysis of solids, liquids and powders may be required. The range of ElvaX Light SDD applications is as wide as the range of XRF method itself.

X-ray Fluorescence has long been one of the key analysis methods in the petrochemical industry. ElvaX Light SDD is ideal for process and quality control laboratories to analyze fuels, lubricants and oils for such elements as sulphur, nickel, vanadium, lead, calcium, phosphorous, zinc, ferrum, natrium etc. Geared with an SDD detector with active area up to 25 mm2 and using state of the art quantative analysis algorithms, ElvaX Light detects most elements in concentrations as low as 1.0 ppm in light matrix. This instrument’s detection range, accuracy and precision are the answer to the needs of the petrochemical industry, in which the concentration of each element is so critical in ensuring correct properties of the final product.

With a completely automated measuring process and an intuitive, user friendly interface, ElvaX Light SDD will for sure enhance efficiency and accuracy of your laboratory. The use of ElvaX Light SDD XRF analyser is constantly increasing throughout Europe, US, Russia, Middle East, India and many other countries worldwide.

The ElvaX Light SDD is ideal for process and quality control laboratories analysing sulphur in fuels, sulphur, nickel and vanadium in fuel oils, and lead in gasoline. To achieve the required oil properties, specific elements such as calcium, phosphorous, zinc, (the additive elements) are added to a base oil, and the concentration of each element is critical in ensuring correct properties of the final oil quality and production control Elvatech’s new ED-XRF unit can also perform the monitoring of FE, Na, Sb and K as process efficiency indicators, monitoring of additives and stabilisers in lubricating oils, regular wear metals analysis in lubricants, determination of S, Ni, Cl, and V levels in waste oil and analysis of petroleum coke

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia