Measurement and Testing

A game changing pH electrode that can be relied upon

May 03 2019

Especially challenging are all oil and gas refinery applications and also petrochemical processes like ethylene quench waters these can be highly corrosive requiring accurate pH measurement and controls to counter costly corrosion damage to the plant.

Oil and gas refineries and ethylene plants processing petrochemicals where quench waters account for a vast majority of the waste streams are very difficult, yet very important locations in which accurate pH measurement and control is needed to counter against costly corrosive damage at the plant. Sour waters tested at these locations will be contaminated with hydrocarbons and contain up to 4% hydrogen sulphide with temperatures of 80 –100ËšC.

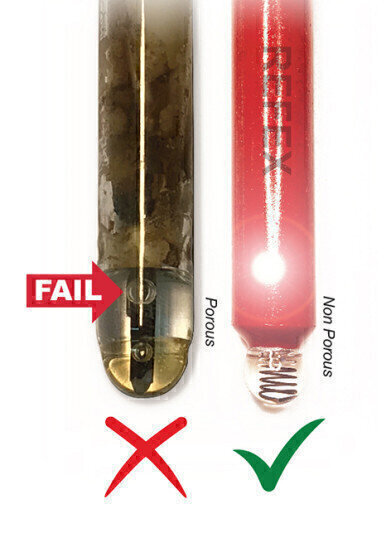

Other tough places where pH measurement is a vital yet very tricky requirement include sulphur recovery units, low, ionic and corrosive boiler feed waters, overhead blow down sour condensate waters, effluent treatment plants with oily discharges and desalter waters in which potassium chloride (KCl) salt is removed by electrolysis. Contaminants such as these will quickly foul and poison any pH sensors with porous reference junctions, so regular ‘fire fighting’ in the form of cleaning, recalibration and expensive and time consuming electrode changes are regular occurrences. The electrode's "weak link" component is always the porous reference junction "diaphragma" where there is a liquid to liquid contact and exchange. Effectively, this is built in obsolescence of all pH sensors.

A solution is at hand. Refex Sensor’s pH/mV sensors have a hard non porous ionically conductive interface/barrier that replaces the now obsolete porous junction (diaphragma). This unique interface barrier doubles as an immobilised electrolyte that protects the mV integrity of the AgAgCl reference by preventing all liquid/liquid contact and exchange between the KCl reference electrolyte that is separated by the interface barrier from the oily/sulphurous corrosive waters being pH controlled.

The Refex non-porous / long life pH sensors are totally resistant to HC fouling and H2S poisoning. The highly reliable Refex pH electrodes remain accurate and low maintenance and perform well many times longer than other pH electrodes in the most extreme oily/sulphurous corrosive waters even at high and varying temperatures and pressures. These electrodes are compatible with Yokogawa, Swan, Knick, Emerson and ABB instruments.

Digital Edition

PIN 25.3 June/July

June 2024

Analytical Instrumentation - Recent Advances In Various Bench Scale Accelerated Oxidative Testing Methods For Fuels - Petrochemical Industry: Anton Paar Solutions Streamline Processes, Reduce H...

View all digital editions

Events

Jul 30 2024 Jakarta, Indonesia

Jul 30 2024 Jakarta, Indonesia

China Energy Summit & Exhibition

Jul 31 2024 Beijing, China

Jul 31 2024 Chengdu, China

Aug 05 2024 Moon Township, PA, USA