Measurement and Testing

NOx converter with increased capacity and reduced energy consumption

Jun 17 2015

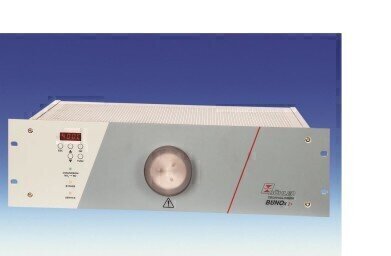

Amongst the numerous new or improved products presented by the gas analysis division of Bühler Technologies GmbH, a German based manufacturer of globally available products for gas analysis, are advanced versions of the BÜNOX 2+ range of NOx converters.

To enable the analysis of NOx in emission monitoring systems with highly cost effective infrared analysers NO2 is converted to NO. This takes place in electrically heated ovens in which typically disposable reactor cartridges filled with metal based exchange material are inserted.

Bühler now has developed an improved conversion material with higher exchange capacity even at temperatures not exceeding 400°C.

Furthermore, within a research project supported by the BMWi*, a completely new carbon based conversion material has been developed by Bühler. This has been achieved by a special treatment step within the production process of the material. Not only that this new material converts safely below 200°C, it does also not produce CO and thus eliminates the need of an additional CO analysis and as additional benefit the consumption of electrical energy is reduced significantly.

Additionally wall mounted NOx converters now enhance the range of the BÜNOX2+ program. These types include versions with 180°C heated gas paths for trace measurement and also unheated units.

An important highlight in the efforts to improve the cost of ownership is the new capacity monitor NOXCal, now part of the standard software of all BÜNOX 2+ units. This allows the operators to determine the exchange point of the converter cartridge in advance and thus contributes to an even more reliable continuous emission monitoring.

For more information please click here or visit us at Achema hall 11.0 booth A43.

* the Federal Ministry of Economy and Technology upon a resolution of the German Federal Assembly.

Digital Edition

PIN 25.3 June/July

June 2024

Analytical Instrumentation - Recent Advances In Various Bench Scale Accelerated Oxidative Testing Methods For Fuels - Petrochemical Industry: Anton Paar Solutions Streamline Processes, Reduce H...

View all digital editions

Events

Jul 30 2024 Jakarta, Indonesia

Jul 30 2024 Jakarta, Indonesia

China Energy Summit & Exhibition

Jul 31 2024 Beijing, China

Jul 31 2024 Chengdu, China

Aug 05 2024 Moon Township, PA, USA