Flow meter

Ultrasonic flowmeter technology has patents expanded

Feb 23 2023

Titan Enterprises has announced the expansion of its patent portfolio for ultrasonic flow technology used in its range of Atrato®, MetraFlow®, and Process Atrato® flow meters.

Titan first began developing a viable, accurate ultrasonic non-invasive small bore measuring device in 2001 as part of a long-term strategic plan. The work resulted in patented ultrasonic technology, which has since led to an expanding line of ultrasonic flowmeters and patents ranging from signal processing methodology to novel mechanical design.

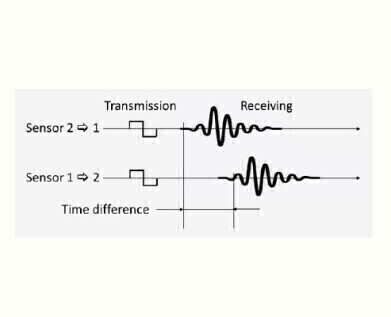

Titan’s ultrasonic flow sensors use high-frequency sound waves to measure flow using the time-of-flight principle within the liquid in a small pipe. The ultrasound is injected with the direction of flow into the liquid by one piezoelectric crystal (the sensor) and is received by a second piezoelectric crystal further down the tube. These crystals then reverse the direction of the ultrasound in the tube, and both time-of-flight acoustic signals are measured. As one sound pulse is accelerated by the velocity of the liquid and the second retarded, the difference in the flight time is twice the fluid velocity, and as the dimensions of the flowmeter tubes are known, the volumetric flow can be calculated.

The Atrato® and MetraFlow® flowmeters are equipped with Titan’s proprietary Interface Software, which overcomes the challenge of measuring fluids that have significantly differing acoustic characteristics, such as viscous organic fluids or elevated temperatures. The software allows users to view the acoustic signal of the measured fluid in real time and adjust its position in the measurement window to ensure reliable flow measurement in the conditions of operation.

Ultrasonic flowmeters are the ideal solution for measuring low flow rates. Titan has developed several generations of ultrasonic low-flow meters based upon their patented time-of-flight design, capable of measuring the velocity of the fluid within the pipe. The Atrato® line of patented ultrasonic inline flowmeters consists of four models operating over a flow range of 2ml per minute up to 20 litres per minute. These low-flow ultrasonic flow sensors offer excellent turndown (> 200:1), repeatability (to ±0.1%), linearity, and accuracy of better than ±1.0% of reading.

Titan’s ultrasonic flow devices are independent of Reynolds numbers and can therefore operate from laminar flow through to turbulent flow. This makes them highly versatile, able to accurately measure liquids ranging from water to high-viscosity oils. Being through-flow devices, they can also be tolerant to impurities in the system, which would cause havoc to meters with moving parts.

The rugged, clean bore construction of the Atrato® and MetraFlow® ultrasonic flowmeters makes these devices ideal for almost any low-flow application, from research and development to industrial processes, and even the metering of chemically challenging liquids. The Process Atrato®, durably constructed from 316 stainless steel and PEEK and incorporating Titan’s patented time-of-flight ultrasonic flowmeter technology, is specifically designed for use in demanding process and control environments.

With the expansion of its patent portfolio for ultrasonic flow technology, Titan Enterprises continues to demonstrate its commitment to developing innovative flow measurement solutions for a wide range of industries.

Digital Edition

PIN 25.4 Aug/Sept

September 2024

Analytical Instrumentation - Novel and Rapid LSC method for the analysis of biogenic carbon in fuels Measurement and Testing - Matrix evaluation on the Xplorer-V with Vectra autosampler accordi...

View all digital editions

Events

Nov 04 2024 Abu Dhabi, UAE

Nov 04 2024 Kigali, Rwanda

Nov 05 2024 Toronto, Canada

Nov 05 2024 Paris, France

Nov 12 2024 Cologne, Germany