Biofuel Industry News

Waste to Energy: Made-to-Measure System for Biogas Production and Waste Disposal

Jun 13 2012

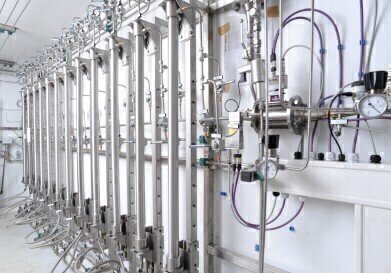

Eisenmann (Germany) has developed a new biogas upgrading system that will give customers direct access to the natural gas pipeline system. Highly selective membrane technology separates the raw biogas and concentrates the methane content to more than 97 percent. As a result, operators can feed the biomethane into the natural gas pipeline without prior treatment. Eisenmann supplies the membrane technology as part of a connection-ready facility.

“This highly flexible, modular process is ideal for low-capacity upgrading,” declares Lukas Graf, a biogas upgrading specialist employed by Eisenmann Anlagenbau GmbH & Co. KG. “The throughput rate can be easily adapted to the customer’s specific requirements. Our equipment can be retrofitted to any biogas plant, not just those built by Eisenmann.” With product modules becoming more and more standardised, the Eisenmann process is an increasingly attractive, economical option for plants that produce less than 500 Nm³/h of raw biogas.

To guarantee operators the ideal solution for their specific plants, Eisenmann’s experts test each system under real conditions in the company’s Technology Center before delivery. The industrial solutions specialist has already sold one biogas upgrading facility featuring highly selective hollow-fiber membranes. It will be employed by a longstanding customer from summer 2012 to process up to 210 Nm³ per hour of biogas per hour. This quantity is equivalent to the annual natural gas consumption of 430 four-person households or 800 LNG-powered vehicles driven 13,000 kilometers per year.

The raw biogas produced by the digester is composed of 55 percent methane and about 45 percent carbon dioxide (CO2). This mixture of gases is filtered at high pressure through hair-thin hollow-fiber membranes that are more permeable to CO2 than to methane. This yields a methane concentration of more than 97 percent. The membranes employed minimise methane loss, which is below one percent.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia

May 06 2024 Houston, Tx, USA