-

Figure 1: Close up of Wasson-ECE patented micro-convection oven for capillary columns.

Figure 1: Close up of Wasson-ECE patented micro-convection oven for capillary columns. -

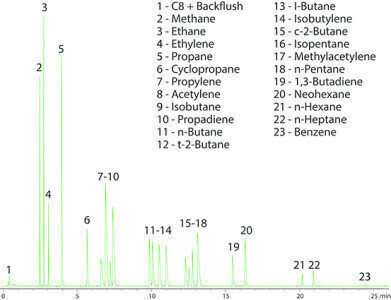

Figure 3: Eclipse FID1 chromatogram showing separation of C1-C7 hydrocarbons and backflush of heavier species.

Figure 3: Eclipse FID1 chromatogram showing separation of C1-C7 hydrocarbons and backflush of heavier species. -

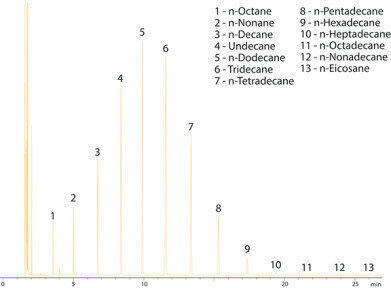

Figure 4: Eclipse FID2 chromatogram showing speciation of C8-C20 hydrocarbons.

Figure 4: Eclipse FID2 chromatogram showing speciation of C8-C20 hydrocarbons. -

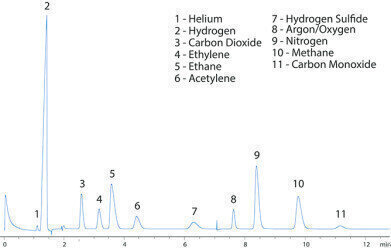

Figure 2: Eclipse TCD chromatogram showing separation of common permanent gases and H2S.

Figure 2: Eclipse TCD chromatogram showing separation of common permanent gases and H2S. -

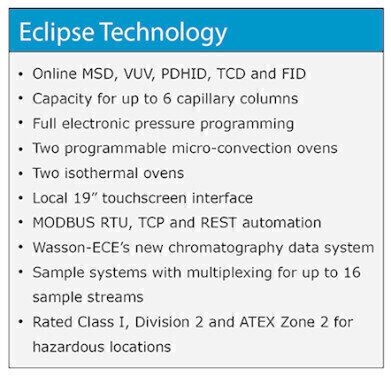

Table 1: Key features enabling lab-quality capillary column chromatography on a process GC.

Table 1: Key features enabling lab-quality capillary column chromatography on a process GC.

Analytical Instrumentation

Process gas chromatography technology eclipsed by new launch

Aug 14 2019

In industry today, especially the hydrocarbon processing industry, the process gas chromatograph (PGC) is an indispensable tool. These fully automated online GCs draw in samples, analyse them for chemical composition and then transmit the results to a plant control computer. Programmed to cycle through several streams, these systems constantly update control systems with respect to process composition objectives and quality specifications.

The efficiency, and thus the value, of a PGC is maximised when the analyses provide as much data as possible. In the laboratory, this is done with the use of high-resolution capillary columns that utilise temperature and pressure programming to produce extensive chromatograms showing the separation, and quantification of complex mixtures.

Eclipse, from Wasson ECE Instrumentation, is a new generation of PGC. The objective in the design of this instrument was the use of true convection ovens, along with electronic pressure programming, to enable the reproduction of laboratory-calibre capillary column chromatography in an on-line chromatograph. Eclipse has two independent, patented Micro-Convection Ovens (MCOs) which provide two unique temperature programmed environments (Fig. 1). There are also two isothermal ovens, each with a separate temperature assignment. This configuration, two independent programmable ovens, and two isothermal ovens, delivers the most flexibility and analytical capability available on the PGC market today.

Super RGA: An example of Eclipse’s comprehensive capabilities

The Super RGA (refinery gas analyser) addresses gas, pressurized liquid, or liquid samples that range from hydrogen to C20. The Super RGA uses four ovens – two temperature programmable and two isothermal – and four detectors – two flame ionization (FID) and two thermal conductivity (TCD). One TCD uses nitrogen carrier gas and quantifies hydrogen. The other TCD uses helium, or hydrogen carrier gas and quantifies carbon dioxide, carbon monoxide, oxygen, nitrogen and hydrogen sulphide. The two TCD signals are summed together so that the resulting single TCD chromatogram encompassing the full range of the TCD analytes (Fig. 2).

The two temperature programmable MCOs each have capillary columns. One oven has two columns and is connected to one of the FIDs to produce a chromatogram of C1-C7 paraffins and olefins plus a C8+ composite peak (Fig. 3). The second MCO has a capillary column which specifically separates the C8-C20 hydrocarbons (Fig. 4). The two FIDs each produce their own chromatogram, and these chromatograms occur at the same time the combined TCDs chromatogram occurs. This comprehensive system produces three chromatograms simultaneously: one combined TCDs and two FID chromatograms. The extensive analyte range covered by this single analyser makes it the broadest ranging PGC in the world.

Thus, four aliquots of the same sample are injected down parallel paths, each aliquot being directed to the column of choice with its own temperature and pressure program. Simultaneous chromatograms are combined into a single digital report and transmitted as needed. Since this one analyser addresses a single sample flow, the resulting multi-detector data provides greater accuracy and with overall reduced analysis time.

Eclipse is, quite simply, the bright new future of process gas chromatography. Typical PGCs monitor 2-3 analytes isothermally from one process stream. Eclipse PGCs can monitor 20 analytes or more by using up to 6 capillary columns interrogating up to 16 sample streams. Moreover, Eclipse chromatographs offer MS, VUV, PDHID, TCD and FID detector combinations, all controlled by dedicated electronic pressure and flow controllers. The result is an online PGC that can finally do what it once took numerous lab GCs to do. The Eclipse suite of fully applicated PGC analysers are ready to transform your HPI processes.

Digital Edition

PIN 25.3 June/July

June 2024

Analytical Instrumentation - Recent Advances In Various Bench Scale Accelerated Oxidative Testing Methods For Fuels - Petrochemical Industry: Anton Paar Solutions Streamline Processes, Reduce H...

View all digital editions

Events

Jul 30 2024 Jakarta, Indonesia

Jul 30 2024 Jakarta, Indonesia

China Energy Summit & Exhibition

Jul 31 2024 Beijing, China

Jul 31 2024 Chengdu, China

Aug 05 2024 Moon Township, PA, USA