Analytical Instrumentation

Next Generation Vapor Pressure Testing

May 18 2021

The MINIVAP VP VISION from Grabner Instruments is a highly versatile and portable vapor pressure tester which measures gasoline, jet fuel, crude oil, LPG and solvents, all with one unit.

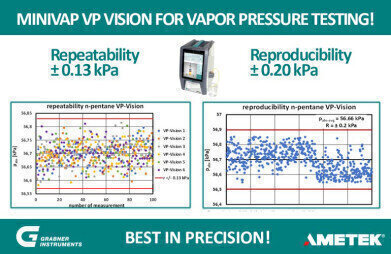

The MINIVAP VP Vision is the first vapor pressure tester to demonstrate excellence in engineering and quality and offers an extended pressure range of 0 to 2000 kPa without compromising precision. Long-term testing has demonstrated an unmatched repeatability of less than 0.2 kPa. In addition, the MINIVAP VP Vision features Grabner´s Sampling Pro™ valve design, which during ruggedness tests proved to be the best-in-class, piston-based design for minimizing cross contamination between various sample types.

Grabner’s Cockpit™ PC software offers lab managers the utmost in flexibility. The software allows users to consolidate measurement results and statistics from multiple locations at one central lab and to store measurement data at any chosen location via direct Ethernet and LIMS-connection. The software can be accessed through a secure VPN tunnel, allowing true mobile access to instruments from any place at any time.

Key Features:

- Premium Vapor Pressure Tester for Gasoline, Jet Fuel, Crude Oil, LPG and Solvents

- Best Pressure Range: 0-2000 kPa

- Simple and Flexible Use

- - One-Button Use - Detailed Analysis with Cockpit™ Software

To learn more about the MINIVAP VP Vision, please click here.

Crude Oil Package – The Official Standard Method for Vapor Pressure of Crude Oil

The Crude Oil Package is a comprehensive solution for the transport and measurement of the vapor pressure of crude oil according to ASTM D6377. The unique Floating Piston Cylinder allows safe sample transfer of “live crude oils” according to ASTM D3700 and eliminates the risk of evaporation of light hydrocarbon ends during transport.

- Floating Piston Cylinder (FPC 250)

Collecting crude oils in constant pressure, floating-piston cylinders can avoid changes in gas/liquid composition. Grabners Floating Piston Cylinder is a stainless-steel cylinder, which was carefully developed in cooperation with offshore personnel. The small and handy cylinder holds 250 mL of sample and allows the collection, mixing, transfer and handling of crude oils. It fully complies with ASTM D3700, D6377 and GOST R 52340 methods.

- Easy to Use

Attach the FPC to the sample source and flush it either manually or purge it with a continuous bypass stream of the sample. Then collect the sample and seal it inside the cylinder.

- Mechanical Stirrer

The FPC includes a built-in mechanical stirrer, to maintain a representative and uniform sample.

- Manual Filling for ASTM D3700

The handle of the mechanical stirrer extends from the air-inlet side and contains a compact pressure gauge to monitor the pressure of the crude oil inside the cylinder. The mechanical stirrer also enables manual positioning, making a back-pressure source in field unnecessary. When the piston is in forward position, the filling of the FPC 250 automatically creates a back pressure of approximately 150 psi of air, which is suitable and sufficient for numerous sampling conditions.

To learn more about the Crude Package, please click here.

Digital Edition

PIN 25.3 June/July

June 2024

Analytical Instrumentation - Recent Advances In Various Bench Scale Accelerated Oxidative Testing Methods For Fuels - Petrochemical Industry: Anton Paar Solutions Streamline Processes, Reduce H...

View all digital editions

Events

Jul 30 2024 Jakarta, Indonesia

Jul 30 2024 Jakarta, Indonesia

China Energy Summit & Exhibition

Jul 31 2024 Beijing, China

Jul 31 2024 Chengdu, China

Aug 05 2024 Moon Township, PA, USA