Measurement and Testing

When is Spectroscopic Polymer Characterisation Used?

Jun 27 2022

From simple polymers such as polyethylene to complex polymeric nanocomposites, spectroscopic analysis is used to characterise a wide range of polymer materials. Read on to find out more about some of the different spectroscopic polymer analysis techniques and their applications.

Developing high-performance thin films

From reducing static electricity to improving adhesion and minimising corrosion, high-performance thin films are used for a myriad of applications. Techniques such as Angular-Resolved X-Ray Photoelectron Spectroscopy (ARXPS) play an important role in developing these products.

Studying the behaviours of biomaterials

Biomaterials have revolutionised modern medicine and are widely used for cardiovascular surgery, dentistry and orthopaedic applications. They’re also gaining traction in the cosmetics industry, where brands covet materials that actively interact with the body’s natural biological systems. Spectroscopic polymer analysis techniques allow scientists to study the characteristics of biomaterials and push the boundaries of modern medicine. Studying the bio-compatibility of titanium medical implants used for dental implants and bone conduction hearing aids is just one application for spectroscopic polymer characterisation in the biomaterials sector.

Engineering high-performance materials

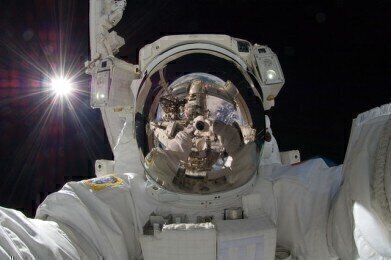

Automobiles, airplanes and even spaceships rely on high-performance construction materials to operate in the harshest conditions. Spectroscopic polymer analysis techniques are critical when it comes to developing these high-performance materials.

For example, Vibrational Spectroscopy has emerged as a useful technique for analysis of polymers and polymer composites. Both Raman and Infrared (IR) techniques are classed as Vibrational Spectroscopy techniques and are used to analyse properties such as molecular structure, chemical composition and chain orientation. These techniques are used to develop ultra-tough polymer materials used by NASA for space exploration, including adhesives, lubricants, circuit boards, electrical insulation and paints.

Developing a “molecular fingerprint”

Near-Infrared (NIR) Spectroscopy is another gold-standard polymer characterisation technique. It’s widely used in the plastics industry for quality control. “Combined with chemometrics, near-infrared (NIR) spectroscopy is now recognised as one of the most important techniques for polymer analyses,” reads an article published in the peer-reviewed journal, Polymers.

“Infrared and Raman studies also offer invaluable means for the analysis of inorganic particles used as reinforcing fillers for polymers.”The authors describe Vibrational Spectroscopy as a way to obtain a “molecular fingerprint” of a polymer material and gain detailed insight into both molecular structure and chemical composition.

With applications for engineering, energy and space exploration, spectroscopic polymer analysis techniques have an expansive reach. But scientists don’t rely exclusively on spectroscopic methods. We spotlight other techniques, including thermal methods such as Differential Scanning Calorimetry (DSC), in ‘Polymer Characterisation - Techniques, Types & Properties’.

Digital Edition

PIN 25.3 June/July

June 2024

Analytical Instrumentation - Recent Advances In Various Bench Scale Accelerated Oxidative Testing Methods For Fuels - Petrochemical Industry: Anton Paar Solutions Streamline Processes, Reduce H...

View all digital editions

Events

Jul 30 2024 Jakarta, Indonesia

Jul 30 2024 Jakarta, Indonesia

China Energy Summit & Exhibition

Jul 31 2024 Beijing, China

Jul 31 2024 Chengdu, China

Aug 05 2024 Moon Township, PA, USA