Analytical Instrumentation

Recycle Gas Hydrogen Measurement Application Note

Jun 20 2018

Application

Continuous Hydrogen measurement in recycle gas in refineries and chemical plants

BackgroundÂ

Hydrogen is one of the most widely used feed stocks in the refining process. Hydrogen is also used in chemical plants to control the polymer manufacturing process.Â

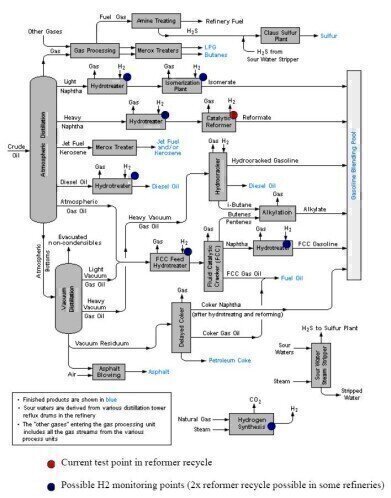

In catalytic reforming processes used for the refining of petroleum products, the measurement of hydrogen in recycle gas is critical to ensure the efficient operation of the plant. Â Continuous measurement of hydrogen in reformer recycle gas ensures the proper efficiency of the catalyst. The process stream is a multi-component including a variety of hydrocarbons, carbon-dioxide and trace amounts of carbon monoxide and chlorides. Currently, traditional process analyzers like gas chromatographs, thermal conductivity meters, density analyzers are used to measure the hydrogen content in the reformer recycle gas. Additional hydrogen measurements are needed in hydrotreaters and reformers where hydrogen is produced for the refining process.Â

Measurement Technique

H2scan analyzers employ a solid-state hydrogen specific technology based on palladium alloys that requires no sample gas, reference cell or everyday calibration. The sensing material is inherently specific to hydrogen and has the capability to operate in a variety of multi-component gas backgrounds. H2scan analyzers are adaptable to conventional or NeSSI type sample systems and provides direct hydrogen measurements.Â

Advantages

Traditional analyzers require regular maintenance, long sampling times, analyzer housings increasing the overall cost to buy / install / maintain. H2scan’s HY-OPTIMA™ 1700 in-line, real time hydrogen-specific process monitors are designed for ease of use, interface flexibility and true process control. The HY-OPTIMA™ 1700 is an intrinsically safe, solid state sensor that is configured to operate in process gas streams with up to 95% relative humidity and temperatures up to 100ºC.H2scan’s inline analyzers can be easily installed using a standard Swagelok connection much closer to the process or in sample housing. Field calibration is possible with standard calibration gases on site.

For further information or to place an order, please contact:

•   Gid Herman at GHerman@h2scan.com or (661) 775-9575 ext. 606

•   www.h2scan.com

Â

Digital Edition

PIN 25.4 Aug/Sept

September 2024

Analytical Instrumentation - Novel and Rapid LSC method for the analysis of biogenic carbon in fuels Measurement and Testing - Matrix evaluation on the Xplorer-V with Vectra autosampler accordi...

View all digital editions

Events

Sep 23 2024 New Orleans, LA, USA

Sep 23 2024 Rio de Janeiro, Brazil

Sep 24 2024 Kielce, Poland

Sep 24 2024 Calgary, Canada

IDW DOWNSTREAM CONFERENCE 2024

Sep 24 2024 Warsaw, Poland