Safety

A New Standard in Flammable Gas Sensing

Apr 18 2016

If you are using a flammable gas detector, then it is almost certainly fitted with either a catalytic bead (pellistor) or infra-red sensor. The sensor converts the combustible gas concentration into an electrical signal that the instrument can process and react accordingly. Both technologies have advantages; pellistors are relatively inexpensive and are sensitive to a wide range of flammable gases, infra-red sensors are extremely robust to environmental contamination and mechanically strong but cannot be used to detect some flammable gases like hydrogen. The choice of technology utilised has often depended on a compromise between cost and reliability.

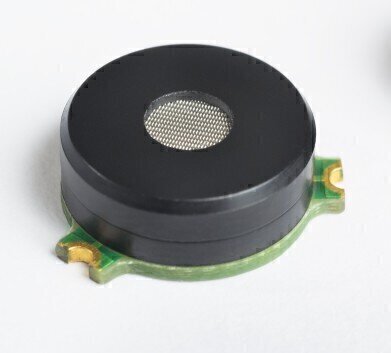

The new MPEL from SGX Sensortech provides instrument manufacturers and instrument users with a third option which removes the need for compromise. The new flammable gas sensor utilises well established catalytic bead chemistry supported by a microelectromechanical system (MEMS) and provides a revolutionary level of sensing reliability.

Some of the key benefits:

- Reduction in operating power – the MPEL when operated constantly uses half the power of a standard pellistor, instantly doubling instrument run time. In addition, the MPEL can also be operated in pulsed mode which further reduces the power consumption giving opportunities for longer run times in portables, longer cable runs or more sensor points per cable run..

- Superior poison and inhibition resistance – the sensor is fitted with novel filtration technology to remove contaminants which occur in typical industrial environments. Its resistance to common poisons such as silicone vapours or inhibitors such as hydrogen sulphide is far superior to existing pellistor technology and will result in a significant increase in sensor lifetime.

- Mechanical robustness - the MPEL uses a unique solid-state design which means that it is more resistant to mechanical shocks and vibration. With an MPEL fitted, an instrument will no longer need to be calibrated, or worse, sent back for sensor replacement when it is accidentally dropped.

- Affordable cost – since the MPEL is manufactured on automated wafer fab and deposition equipment, it is available at a competitive price and considerably below that of infra-red technology.

If you are a designer and manufacturer of either portable or stationary flammable gas instrumentation, the SGX Sensortech MPEL provides you with a product fully capable of meeting your customers’ flammable sensing needs. Whether you are looking to design smaller instruments using the MP-7217, increase operating run time or reduce overall cost of ownership, the next generation MPEL technology can provide the answer. It is also available as the VQ548MP in an industry standard packages, provided with full safety certification and can be used as a drop in replacement for your existing sensor with little or no circuitry modification.

If you’d like to learn more about the revolutionary technology included in the MPEL or wish to see for yourself the performance you can achieve, then please contact one of our knowledgeable sales team or our network of local distributors for more information or samples for evaluation.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 22 2024 Hannover, Germany

Apr 22 2024 Marrakech, Morroco

Apr 22 2024 Muscat, Oman

Apr 22 2024 Rotterdam, Netherlands

Apr 23 2024 Singapore

.jpg)