Pour Point

Huber offer accurate temperature control for Pour Point testing

Apr 20 2011

As temperatures required for carrying out chemistry in research have become lower and lower, Huber created a case study designed to show the performance and control of the Unistat circulation thermostat range at low temperatures. This case study demonstrates how the process temperature inside an Asahi vacuum insulated glass reactor can be comfortably cooled and controlled at -110 °C by using a Unistat 1005w, making it ideal for low temperature testing.

The Unistat 1005w has a temperature range of -120 to +100°C, and cooling power from 1.5kW at -40, 1.4kW at -80 and 1.0kW at -100. The heat transfer fluid used in the case study was Kryothermal S. As the Unistat 1005w has a low internal volume, it requires minimal thermal fluid and as a result is able to react swiftly to temperature requirements transferring energy to where it is needed – the process.

The Unistat 1005w was connected to the Asahi 10 litre triple wall reactor with two 1.5 M30x1.5 meter hoses. The reactor was filled with 10 litres of M90.055.03 silicone oil with a temperature range of -90 to +55 °C. The stirrer speed was set to 200 rpm.

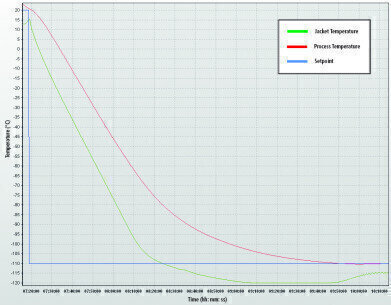

The Unistat was set to process control, meaning that the temperature was monitored from within the process rather than from within the Unistat. The starting temperature was 20°C and setpoint of -110 °C was entered. The results were recorded using the Huber “Spyware” software, which records the temperature of the process and shows in graphic form how the Unistat reacts to control the temperature of the process.

The jacket temperature cools quickly in a linear fashion to -100 °C in approximately 55 minutes (ramp rate of 2 K/min) before slowing and reaching a “Tmin” of -120 °C. The graphic shows how the process temperature follows and reaches -110 °C in 150 minutes and is maintained at -110 °C with the jacket temperature at -115 °C.

To find out more about the Unistats ability to react to temperature changes, see our selection of over 200 case studies at www.huber-online.com

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia