Analytical Instrumentation

XRF for Complying with Maritime Emissions Regulations

Feb 24 2017

Air and water quality are becoming increasingly important concerns for the shipping and boating industries. As part of ongoing efforts to reduce accumulating pollution released from burning fossil fuels, the International Maritime Organisation (IMO) recently announced that the Maritime Protection Committee (MEPC) agreed to implement the proposed 0.50% global SO cap on marine fuels on January 1, 2020. This is a significant reduction from the current limit of 3.50% which has been in place since 2012. Within sulphur emission control areas (ECA), the sulphur limit remains at the 0.10% level established in 2015. ECAs are established in the Baltic Sea area, North Sea area, North American area, United States Caribbean Sea area and three regions in China – the Pearl River Delta, Yangtze River Delta and Bohai Sea Region.

In the EU, new requirements are being placed on ships over 5,000 gross tonnage to monitor and report on carbon dioxide emissions (CO²), fuel consumption and cargo carried. Ships this size account for 55% of all ships calling into EU ports and 90% of related emissions. These requirements are part of an effort to understand the potential for reducing greenhouse gases and potentially charge for the emissions with the goal of making shipping more environmentally friendly. Regulation (EU) 757/2015 on the monitoring, reporting and verification of carbon dioxide emissions from maritime transport requires companies to submit a monitoring program, including the method chosen to monitor emissions by August 31, 2017. Beginning January 1, 2018 companies will be required to monitor emissions from impacted ships. Sulphur content in fuels reduces their heating values and increases their CO²-to-heat contents. Taking on fuel with lower sulphur content and verifying its concentration can be part of an emissions reduction program.

Ports will use a variety of control measures, including requiring International Air Pollution Prevention (IAPP) certificates, collecting verification samples from fuel taken on board and other surveillance techniques. On-board sulphur testing is a simple, reliable and affordable way to ensure compliance to maritime emission regulations and avoid delays, fines, sanctions, vessel forfeiture or other penalties.

One of the most efficient and prolific techniques for measuring sulphur content in fuels is energy dispersive X-ray fluorescence (EDXRF). EDXRF analysis is rapid (on the order of seconds or minutes), non-destructive, requires no sample preparation and has low operating costs. The global petroleum community trusts EDXRF spectrometers for upstream and downstream quality control, and it is also a common technique used by on-shore test laboratories. The same testing can be performed reliably by minimally trained staff on a ship following accepted test methods outlined in ISO 8754, IP 336 and ASTM D4294 amongst others.

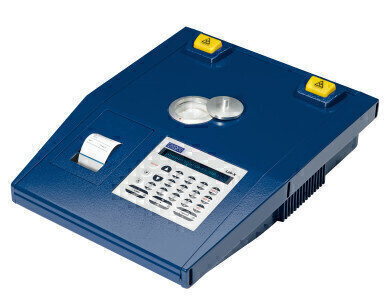

Making it easier to operate a quality test programme, some EDXRF spectrometers provide printed hardcopy reports for record retention, use specially designed sample cells that protect against potential damage caused by leaks, perform automatic instrument stabilisation to ensure reliable results, require no gases or special tools for analysis and take up as little bench space as a laptop. Some manufacturers offer a turnkey solution by delivering the instruments with factory-loaded calibrations following standard test methodology developed by applications experts using certified, traceable reference materials. With a simplified user interface, operators have the ability to create or adapt their own calibrations. As an additional benefit, EDXRF instruments are expandable to accommodate future requirements such as lower regulatory limits on sulphur (EDXRF norms permit sulphur analysis to low ppm range) or the inclusion of additional elements.

As maritime emissions regulations change, EDXRF can be depended upon to provide fast, reliable and easy fuels analysis.

Contact Oxford Instruments for more information.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 22 2024 Hannover, Germany

Apr 22 2024 Marrakech, Morroco

Apr 22 2024 Muscat, Oman

Apr 22 2024 Rotterdam, Netherlands

Apr 23 2024 Singapore