Analytical Instrumentation

Versatile Online Viscometer makes Real-Time Viscosity Monitoring Easy and Cost-Effective

Feb 27 2014

Viscosity measurement specialist Hydramotion Ltd (UK) is pleased to announce an important extension to the certification of its intrinsically safe XL7-15x series process viscometers. These instruments are now available certified to ATEX Ex II 1GD for use in Hazardous Areas where combustible dust as well as explosive gas may be present.

The extension certifies that the XL7 is fully compliant with all the relevant IEC standards and meets all the relevant Essential Health and Safety Requirements set out in Annex II of the ATEX Directive 94/9/EC. It widens still further the range of applications for the XL7-15x series, which is already certified for use in Zone 0 Hazardous Areas (presence of explosive gas), equivalent to Class 1, Division 1, Group A in north America.

Hydramotion intrinsically safe viscosity measurement systems are widely used in petrochemical plants around the world. With the extended certification, XL7 viscometers are ideal for applications such as the measurement of coal/oil slurries, where finely-divided coal dust presents a significant combustion hazard.

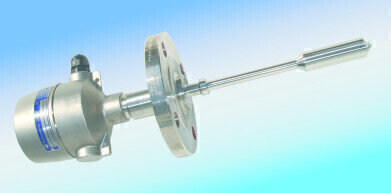

The high-performance XL7 is a field-hardened, rugged instrument that can be used in any fluid under any process conditions, including high temperatures and pressures. As the transducer has no moving parts, seals or bearings that could wear out or fail in service, it needs virtually no maintenance and no on-site recalibration — ideal for hazardous or dangerous environments, where it is often desirable to restrict the degree of access.

Capable of measuring any fluid in any process, the XL7 is one of the most robust and adaptable viscometers on the market. The latest model stores all instrument-specific data on the transducer, giving complete flexibility of installation. The associated VP550 digital readout unit, which can be mounted up to 1000 metres from the transducer, offers a choice of outputs, including three fully-configurable 4-20 mA analogue signals and a more comprehensive RS485 serial data link for remote viscosity monitoring or control.

Ready for use straight out of the box, the XL7 provides continuous real-time viscosity measurement with high resolution, excellent repeatability and virtually unlimited range. The standard sensor is an all-welded 316 stainless steel construction which may be mounted in any orientation in any tank or pipe, no matter what size, using whatever process fitting the customer specifies. If necessary, other materials such as special alloys can be used for the sensor, or a custom coating such as PTFE can be applied to the sensing element.

The XL7 is factory-calibrated to certified viscosity standards traceable to NIST and requires no on-site calibration. Calibration is unaffected by installation or environment .

The sensor always operates at the fluid temperature, which eliminates the chance of potential errors arising from localised cooling of the fluid. The latest high-temperature HT2 model can be used at up to 450 degrees C (842 degrees F) without special cooling, while high-pressure models are rated at 20,000 psi (1380 bar) or greater. Measurements are unaffected by variations in flow rate or by the presence of suspended solids or gases. The sensor naturally rejects typical plant vibration frequencies, which gives a very high output stability even in extremely noisy wellhead or refinery environments. The result is a reliable, easy-to-use and durable viscosity measurement system with an unbeatably low cost of ownership.

With such a combination of toughness, resilience and flexibility, the XL7 is the viscometer of choice for any oil industry process, no matter how harsh or aggressive the measurement conditions.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 22 2024 Hannover, Germany

Apr 22 2024 Marrakech, Morroco

Apr 22 2024 Muscat, Oman

Apr 22 2024 Rotterdam, Netherlands

Apr 23 2024 Singapore