Analytical Instrumentation

Advanced instruments & digital services boost availability and reduce maintenance costs

Jul 17 2019

The Oil & Gas industry operates in tough environments with challenging operational demands across the sector. In complex, often remote operations, it’s difficult to know the condition of equipment, which can lead to costly unscheduled maintenance and downtime when things go wrong.

Plant managers and engineers are looking for opportunities to lower operational costs and risks and improve maintenance efficiency. Preventive and predictive maintenance are particularly in focus to avoid unplanned downtime.

So how do you increase availability and efficiency of your plant as well as have better visibility into your plant assets?

How advanced instruments & digital services can support you

There can of course be no one-size-fits-all IIoT solution, but digitalisation promises huge benefits to boost availability and reduce lifecycle costs by unlocking and putting field instrumentation data to work.

The World Economic Forum estimates a potential $150 billion industry value of digital predictive maintenance initiatives and technologies between 2016-25 (Digital Transformation Initiative: Oil and Gas Industry White Paper, World Economic Forum, January 2017, p.13).

Turning field data into actionable information

A range of Endress+Hauser smart instruments for the oil and gas industry, including flow, level, and some analytical devices, are equipped with Heartbeat Technology that provides high system availability with minimal effort.

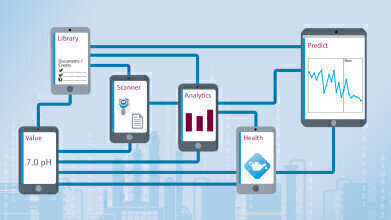

Heartbeat is at the foundation of an ecosystem that is unlocking the vast, largely untapped potential of field instrumentation, process and plant data to create real value.

Heartbeat provides permanent diagnosis of your instruments and processes, verifies performance without process interruption, and monitors process data for trend analysis to support optimisation. This visibility into the condition of your devices and processes makes predictive maintenance possible.

Greater insight and value with digital services

Pairing the huge amount of data from your field devices with Netilion, Endress+Hauser’s growing cloud-based IIoT ecosystem takes maintenance management to the next level and enables the deployment of preventive and predictive maintenance strategies to optimise your processes over the entire life cycle.

Built upon more than 15 years’ experience of Life Cycle Management concepts, this platform and growing portfolio of intelligent apps unlocks the full potential of your field instrumentation to give you more information and insight to vastly improve maintenance efficiency.

Find out more about how you can reduce downtime, increase plant availability and enable predictive maintenance with Heartbeat Technology and Netilion digital services.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 24 2024 Mumbai, India

Apr 24 2024 Jakarta, Indonesia

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea