-

-

Figure Two: An DVLS Reaction Oven module to hold and heat the inert reaction coil.

Figure Two: An DVLS Reaction Oven module to hold and heat the inert reaction coil. -

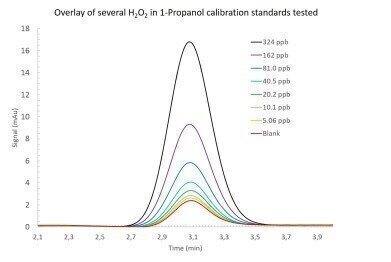

Figure Three

Figure Three

Analytical Instrumentation

Safe & Fast Method for the Analysis of Peroxides in Hydrocarbon Streams

May 19 2020

Peroxides present a potential safety hazard during production and storage. They also have a negative effect on fuels and fuel systems by reducing the octane rating in gasoline. To monitor the trace amounts of peroxides Da Vinci Laboratory Solutions has developed a chromatographic solution based upon a flow injection analysis as a safe and fast alternative to the traditional analysis methods, such as ASTM D2340 and ASTM E299.

This solution has been introduced in 2016 as the DVLS Fast Peroxide Analyser (FPA). The FPA system is based upon an Agilent 1260 infinity II HPLC stack configured with a dedicated reaction oven module to automate the safe, fast and precise analysis of active oxygen originated from hydrogen peroxides and other organic peroxides.

Flow Injection Analysis

To solve the air interference issue of the traditional analysis methods a flow injection technique is used for the Fast Peroxide analysis. The analysis of Peroxide, as active Oxygen, is based on the oxidation of Iodide by Peroxide:

ROOH + 2I- + 2H → ROH + I2 + H2O

Two reagents: Acetic Acid in n-Propanol and Sodium Iodide in n-Propanol are mixed, resulting in a stream of acidified Iodine solution in n-Propanol. The sample is injected into this stream. Subsequently, the liquid stream is lead through a heated inert reaction coil. Iodine is formed under temperature controlled conditions inside the dedicated reaction oven developed by Da Vinci. After passing the reaction coil the HPLC UV detector spectrophotometrically determines the formed Iodine, which is proportional to the level of peroxide.

Dedicated Configuration

The DVLS Fast Peroxide Analyser is based upon the Agilent 1260 Infinity II Liquid Chromatograph (LC) configured with:

- A Quaternary Pump

- An Automatic Liquid Sampler

- An UV Detector for a single wavelength detection

- An DVLS Reaction Oven module to hold and heat the inert reaction coil (Figure Two)

The reaction oven developed by Da Vinci enables an optimal heat distribution to the reaction coil. The oven design matches the HPLC modules thus allowing stacking of the oven between the autosampler and the detector.

Wide Application Range

The Fast Peroxide Analyser was initially developed to monitor peroxides in alpha-olefinic streams, it can also be used to determine peroxides in different matrices such as:

- 1,3-Butadiene

- Aqueous process streams

- Glycols

- Styrene

Performance at ppb level

Linearity, detection limits and repeatability were determined by analysing a series of Hydrogen Peroxide dissolved in 1-Propanol at a concentration range of 5 up to 324 μg/L active Oxygen (Figure Three). Each concentration level was analysed in tenfold, resulting in an LOD of 9.52 ppb w and LOQ of 28.8 ppb w.

Key Benefits:

- Safe and automated alternative to traditional wet chemistry analysis methods

- Wide application range: from alpha-olefinic streams to 1,3-Butadiene, Aqueous process streams, Glycols and Styrene

- Excellent performance down to ppb level

- Configuration based on the standard Agilent HPLC modules saves benchspace

- Fast analysis in less than 5 minutes.

Interested? Contact Da Vinci Laboratory Solutions for more information.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 22 2024 Hannover, Germany

Apr 22 2024 Marrakech, Morroco

Apr 22 2024 Muscat, Oman

Apr 22 2024 Rotterdam, Netherlands

Apr 23 2024 Singapore