-

Figure One: LGI 8890

Figure One: LGI 8890 -

Figure Two: Pressure Station

Figure Two: Pressure Station -

D7756 & D 2163 analysis

D7756 & D 2163 analysis

Analytical Instrumentation

Dual analysis of Residues & Hydrocarbons in LPG using the DVLS LGI

Oct 15 2019

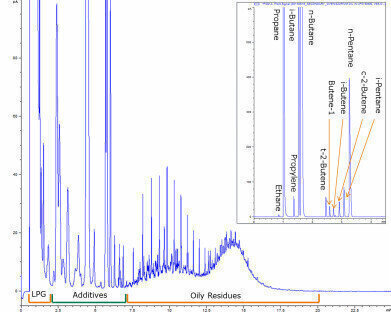

The DVLS Liquefied Gas Injector is a dedicated GC solution for high pressure liquid sampling of C3 - C4 streams such as Liquefied Petroleum Gas (LPG). Standardised as ASTM D7756 and EN 16423 the Liquefied Gas Injector (LGI) determines the residues in LPG. Configuring additional hardware extends the residues analysis to simultaneously determine the hydrocarbon composition of LPG using the same sample cylinder.

Oily Residues in LPG ASTM D7756

The LPG fuel specification ASTM standard D1835-16 lists the LGI method ASTM D7756 as an alternative method for residues analysis. Da Vinci developed the Liquefied Gas Injector as a safe, accurate and fast alternative to ASTM Method D2158 and/or EN Method 15470-1. The on-column injection of the LGI is based on a proven fuel direct injection technique used by the automotive industry to inject fuel into the automotive engine combustion chamber. Featuring the liquefied gas injection under pressure eliminates the need for evaporation of flammable LPG samples.

The LGI is configured on top of the Gas Chromatograph and consists of a high pressure injection valve connected to an injection needle. To allow a representative sample injection, a Pressure Station (as displayed in Figure Two) is used to maintain the liquid sample in a liquid phase under constant pressure during the injection. The sample cylinder is installed on a pressure station using standard quick connectors. For liquid samples in cylinders the Pressure Station is connected to high pressure Nitrogen to control sample pressure. The residue analysis itself is based on boiling point separation of oily residues and contaminants.

The Pressure Station is versatile product and can also be configured for gas samples to analyze various gas compositions. For laboratory safety the waste sample is vented to a central waste system.

Hydrocarbon Composition of LPG ASTM D2163

The LGI application dedicated to the hydrocarbon compositional analysis of LPG complies with ASTM D 2163 and ISO 7941. For a dual analysis of the residue content and the hydrocarbon composition, a Liquid Sampling Valve is added to the GC system with a Split/Splitless inlet, an FID detector, an analytical column and an external GC oven.

The dual analysis of ASTM D7756/EN 16423 and ASTM D 2163/ISO 7941 requires an analysis time of less than 30 minutes.

Wide Application Range

Several case studies demonstrate an excellent and fast performance of the LGI. The case studies are described in the various application notes. Download the application notes to learn more on the various applications of the LGI such as:

- Oily residues and light contaminants in LPG (ASTM D7756, EN 16423)

- Hydrocarbon composition of LPG (ASTM D 2163, ISO 7941)

- Sulfur compounds in liquefied petroleum gases

- Elemental Sulfur in LPG’s

- Desulfurization additives in LPG: DIPA, MEA & DEA

- Inhibitors, additives and Dimers in Butadiene: ACN, ρTBC, Butadiene Dimer

- Nitrogen, carbon dioxide, hydrogen sulfide and C1-C36+ hydrocarbons in unstabilised gas condensate

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 24 2024 Mumbai, India

Apr 24 2024 Jakarta, Indonesia

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea