Analytical Instrumentation

Determine the composition of refinery gases & LPG in 5 minutes

Mar 18 2020

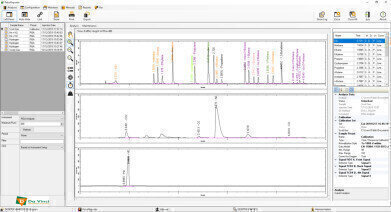

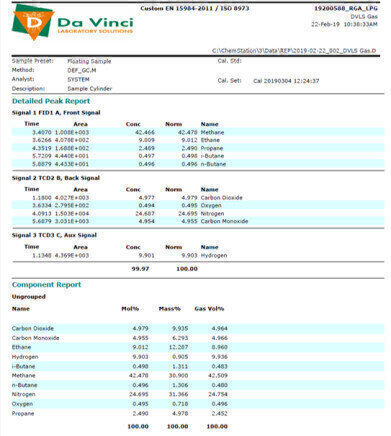

To characterise the hydrocarbon content, permanent gases and Hydrogen Sulfide in refinery & liquefied gases Da Vinci Laboratory Solutions (DVLS) developed a solution based upon the Agilent 8890 Gas Chromatograph. In only 5 minutes the DVLS Refinery Gas Analyser determines the hydrocarbon composition and the permanent gases. The analysis including H2S requires 7 minutes. Using the DVLS PetroReporter software the analyser also reports the calculation parameters such as Calorific and BTU value.

Unique Hardware design

The DVLS Refinery Gas Analyser (RGA) is based upon the Agilent 8890 Gas Chromatograph (GC) containing three different channels. The gas samples are simultaneously injected into the three separate channels.

The FID channel determines C1-C5, C6+ group, the Back TCD channel separates Oxygen/Argon, Nitrogen, Carbon Monoxide, Carbon Dioxide and Hydrogen Sulfide. The Aux TCD channel determines Helium and Hydrogen.

To maximise the system uptime Da Vinci developed a side carrier to contain the valves and a separate heated zone for the Molsieve columns. This unique hardware design includes a built-in column conditioning which reduces the system downtime during the periodical regeneration of the columns.

Customised Analysis

To customise your refinery gas analysis various hardware options are available:

- a mode for extended refinery gas analysis up to BTEX

- a Hydrogen carrier gas

- a Liquid Sampling Valve (LSV) for the sampling of liquefied gases

- a Pressure Station for a representative sampling of (liquefied) gases

- a Vacuum Pump for sample introduction through the use of Tedlar bags

- Inert valves for the use of corrosive gases

- a Fourth channel containing:

- - a Gas sampling valve (GSV)- Column – Detector

- - a Methanizer for the trace analysis of CO/CO2

Standard Methods Compliance

The Refinery Gas Analyser complies with the various ASTM, DIN, EN, IP, ISO and UOP standard test methods to determine the composition of the refinery & liquefied gases.

Automated Reporting of Gas Properties

The GC is controlled by Agilent OpenLab software. The DVLS PetroReporter software automates all aspects of the calibration, gas analysis through reporting of gas calculations. Some examples of the calculations are the Carbon content, Emission factor, Calorific Value and BTU, Liquid volume and Molar mass.

The DVLS PetroReporter is compatible with chromatographic data systems (CDS) of major suppliers including the new OpenLab 2.x (Client-server). PetroReporter can be used either stand-alone or in a network configuration.

Key Benefits:

- The Refinery Gas Analyser is based upon the Agilent 8890 GC configured with dedicated columns, valves, inlet and detectors.

- The multi-channel configuration allows to inject gas samples into the separate channels at the same time. All channels operate simultaneously to provide a fast gas analysis in less than 5 minutes.

- The unique hardware design of the side carrier reduces the system downtime during the periodical regeneration of the molsieve columns.

- Several hardware options are available to customise the analysis, such as LSV, GSV and Pressure Station.

- The Gas Analysers comply with the various standard test methods.

- The PetroReporter software processed the data and reports all calculations necessary.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia