-

-

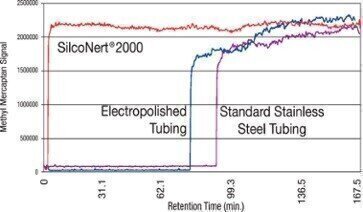

SilcoNert-coated sample flow paths yield nearly-instant signal from instruments.

SilcoNert-coated sample flow paths yield nearly-instant signal from instruments. -

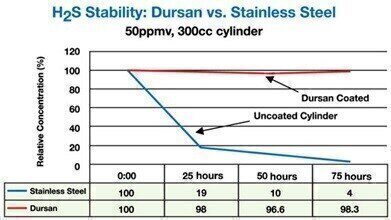

Dursan-coated sample cylinders retain almost 100% of H2S samples after 3 days. Uncoated cylinders consume nearly the entire sample within one day.

Dursan-coated sample cylinders retain almost 100% of H2S samples after 3 days. Uncoated cylinders consume nearly the entire sample within one day.

Measurement and Testing

Improve Analytical Reliability and Accuracy with Inert Coatings

Sep 21 2016

The need to measure trace (ppm or lower) sulfur, mercury, and other emissions is substantial and growing worldwide. However, the stainless steel flow paths of instruments used to measure these compounds are not suited for such low-level sampling. SilcoNert®- and Dursan®- coated instrument flow paths produce virtually instant readings with superior accuracy because critical compounds will not adsorb to the inert-coated surfaces.

Even electropolished flow paths take well over an hour to produce a signal without inert coatings. With them, analysts can start to see results within seconds of injecting the sample. This saves tremendous costs in the form of higher daily sample throughput, less labour, and compliance to environmental regulations.

The benefits of inert coatings aren’t just limited to better instrument performance. Collecting samples off-site once entailed a frantic race to the lab to test them before important molecules were scavenged by the metal sample storage vessels. With SilcoNert- and Dursan- coated sampling equipment, trace-level samples can be adequately maintained for as long as two weeks without loss.

SilcoTek coatings offer the chemical resistance/inertness of PTFE but dramatically improved durability, temperature resistance, and adhesion. A SilcoTek coating can be used at 450°C and sometimes greater, whereas PTFE is destroyed above 230°C. SilcoTek’s innovative chemical vapour-deposited (CVD) treatments are bound molecularly to the substrate so they won’t flake, even on tubing that is bent or flexed.

Trust SilcoNert® and Dursan® coatings for any analytical application to:

- Improve instrument performance and analytical accuracy

- Decrease sample loss and analyte adsorption

- Prevent corrosion

- Reduce the impact of moisture in samples

- Increase durability and temperature resistance

- Easily integrate coatings into existing or new systems – just send your parts to SilcoTek for service or contact an Approved Partner to purchase already-coated parts

Want to learn more? Click here to view SilcoTek’s 'Improving Sampling Reliability and Corrosion Resistance' white paper or visit their website.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 22 2024 Hannover, Germany

Apr 22 2024 Marrakech, Morroco

Apr 22 2024 Muscat, Oman

Apr 22 2024 Rotterdam, Netherlands

Apr 23 2024 Singapore