Flow Level Pressure

£1m Invested in UK’s Foremost High Pressure Calibration Facility

Jul 30 2015

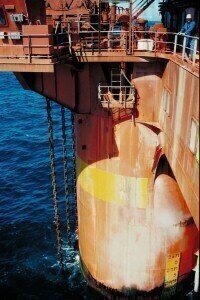

NEL (UK) is investing £1million to create the UK’s only flow meter calibration facility capable of testing at significantly elevated pressures and temperatures.

This new test loop will reduce oil and gas operators’ financial exposure by performing meter calibrations closer to actual service conditions. By more accurately reflecting the increasing temperatures and pressures at which flow meters must operate, the uncertainty of meters deployed in the field will be minimised significantly.

Douglas Griffin, Head of Petroleum Measurement & Allocation at the Oil & Gas Authority, said: “Both equipment manufacturers and operators face significant flow measurement challenges, with elevated temperatures and pressures causing a substantial gap between calibration and actual service conditions.”

The pressure capability of NEL’s high pressure/high operating temperature liquid flow loop will increase from 5 bar maximum capability to 100 bar, with its ability to deal with higher temperatures increasing from 400C maximum capability to 800C. The new facility will be fully operational during quarter three.

NEL’s Flow Facilities are already widely recognised as one of the best in the world and are the primary flow measurement standard for the UK, under the UK’s National Measurement System (NMS)*.

Dr Phil Mark, Group Manager, NEL said: “NEL’s investment means that the UK is leading the improvement of flow meter performance in ever more challenging operating conditions. NEL’s new high pressure/high operating temperature liquid flow loop fills the gap between calibration and service conditions, allowing manufacturers to prove the performance of their meters, while operators and taxation authorities can be assured of more accurate fiscal measures.

“The findings from a recent Joint Industry Project, co-ordinated by NEL, into the effect of changing temperature and pressure on Coriolis meter performance was a principal driver,” concluded Dr Mark.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia