Flow Level Pressure

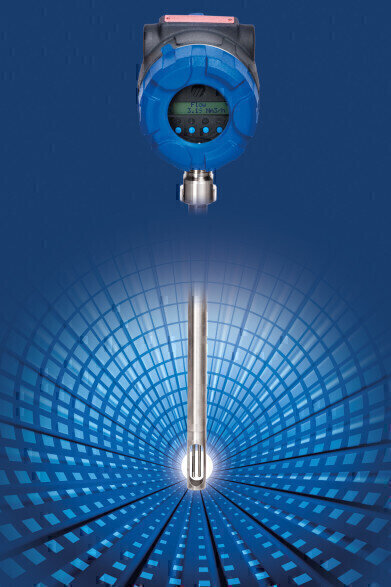

Direct Mass Flow Rate Measurement for Industrial Process Applications

Mar 31 2015

There are many well-established technologies used to measure the flow rate of gas within industrial process operations. While mass flow rate is the ideal measurement for typical process applications, common measurement methods, including differential pressure, vortex shedding, and ultrasonic, among others, measure actual volumetric flow rate and not mass flow rate. Therefore, flow meters based on these technologies must correct for temperature and pressure conditions in order to provide an accurate measurement of mass flow rate.

Thermal mass flow technology, a more recent approach to gas flow measurement, does not require correction for changes in process temperature. As a result, the adoption rate for this technology is rapidly increasing. As a newer mass flow rate solution, however, many process control professionals aren’t familiar with how thermal dispersion mass flow meters work – and their advantages.

Technology Advantages. Thermal Mass Flow offers many advantages over other, more traditional, methods of measuring gas flow.

Excellent Low Flow Sensitivity. Thermal technology can measure velocities down to 10 standard feet per minute – much lower than any other flow device. The heat transfer rate is greatest at low flow rates and decreases as the flow rate increases. This makes this technology especially sensitive for low velocity measurement and high turndown requirements.

Excellent Turndown. The Model TA2 thermal mass flow transmitter offers the ability to measure low velocities as well as high flow rates. This can provide a turndown rate of 100:1 or more, depending upon the application requirements and calibration of the instrument.

Low Pressure Drop. The insertion probe has little blockage of the pipe, thereby creating very low pressure drops.

Ease of Installation. Using an insertion probe, the instrument can easily be installed in a pipe or duct. Many installations use a compression fitting or a retractable probe assembly for inserting the probe into the pipe.

Factory Calibration. Instruments are calibrated by leading manufacturers for application-specific requirements and user specifications. This allows the instrument to be installed and placed directly into service without the need for field setup, calibration or adjustment. MAGNETROL calibrates all Model TA2 thermal mass flow meters.

Low Installed Cost. No additional instrumentation is required to obtain a mass flow measurement using a thermal dispersion mass flow meter.

More information? check out http://magnetrol.com/thermalmassflow

Digital Edition

PIN 25.2 Apr/May

May 2024

Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector - Advancements and...

View all digital editions

Events

May 13 2024 New Orleans, LA, USA

May 14 2024 Tashkent, Uzbekistan

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Lund, Sweden

May 15 2024 Copenhagen, Denmark