-

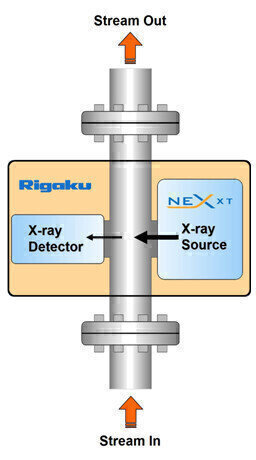

X-ray Transmission (XRT) principle of operation.

X-ray Transmission (XRT) principle of operation.

Analytical Instrumentation

Real Time Sulphur Measurement for Blending and Quality Control of LSFO

Aug 14 2014

Ensuring adequate supplies of 1.00% sulphur (16S) bunker fuel oil to satisfy European demand in emission controlled areas (ECAs) as well as complying with recent North American ECA guidelines affecting the availability of Low Sulphur Fuel Oil (LSFO), continues to be a challenge.

The effect of the requirements of blending operations to produce 1.00% S fuels on fuel quality is also a concern.

To address the tougher quality control (QC) requirements and more rigorous blending operation conditions for LSFO, Rigaku, a global leader in X-ray analytical instrumentation, has engineered a 3rd generation X-ray Transmission (XRT) sulphur process gauge.

With uniquely engineered hardware and novel proprietary software technologies, the Rigaku NEX XT system is faster, more sensitive and far more compact than previous generation systems and provides continuous, reliable detection of sulphur at pressures up to 1480 psig and 200ºC. Sulphur may be quantified from 200 parts-per-million (ppm) to 6.5 wt. %, with analysis times as short as 1 second. The Rigaku NEX XT can operate as a stand-alone analyser or provide real time closed loop control when tied into a blending or plant wide automation system.

Among its other key features are a simplified user interface, reduced standards requirement, automatic density compensation, automatic water compensation, password protection, and standard platform for communicating sulphur, density, and water content to a Distributed Control System (DCS).

Employing the X-ray Transmission (XRT) measurement technique, the Rigaku NEX XT continuously measures a process hydrocarbon stream that passes through an internal flow cell (see Schematic 1). Unlike older generation XRT sulphur analysers, the Rigaku system contains no dangerous radioisotope sources and requires no routine maintenance.

Globally, the petroleum industry continues to employ tens of thousands of radioisotopes in activities that range from exploration and production to distribution. Whether protecting the customer base or corporate shareholders, technology – like the Rigaku NEX XT – now exists to eliminate the risk associated with owing previous generation isotope-based technologies while providing vastly superior analytical results.

Digital Edition

PIN 25.2 Apr/May

May 2024

Safety - Carbon monoxide toxic and flammable gas detection Analytical Instrumentation - Density: A fundamental parameter at critical stages within the petroleum sector - Advancements and...

View all digital editions

Events

May 18 2024 Rio de Janeiro, Brazil

May 19 2024 Minneapolis, MN

May 20 2024 Columbus, OH, USA

May 20 2024 Dubai, United Arab Emirates

May 23 2024 Beijing, China