Analytical Instrumentation

CRYSTEX® QC, a truly automated system for Soluble Fraction measurement in Polypropylene plant control

Nov 19 2014

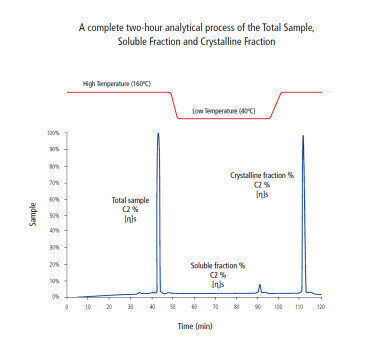

Developed by Polymer Char, this new approach quantifies the amorphous phase through the separation capability of TREF, it is very simple to operate, reduces manpower and analysis time significantly, and provides a vast amount of information including Ethylene Content and Intrinsic Viscosity for the whole sample, the soluble fraction, and the crystalline fraction also.

CRYSTEX® QC has been designed for continuous operation at process and Quality Control laboratories of polypropylene manufacturing plants. It stands as the modern alternative to the traditional gravimetric method based on xylene solubility, which is known for being time-consuming and tedious for requiring constant manual handling of solvent at high temperature. This new system overcomes all the difficulties related to the traditional method because it is extremely easy to operate, it eliminates sample weighing, external filtration, and it reduces the time of analysis down to two hours. Furthermore, it requires minimum bench space and utilities.

Unlike other semi-automated approaches, no handling of any solvent or external filtration is required by the operators for the CRYSTEX® QC analysis.

The crystalline and amorphous fractions are separated through a Temperature Rising Elution Fractionation (TREF) technique. Accurate and precise quantification is achieved by means of an infrared detector (IR4), that also measures Ethylene Content for the whole sample, the soluble fraction, and the crystalline fraction. For a truly complete analysis, intrinsic viscosity is also measured for all three parts of the sample by means of a built-in dual capillary viscometer without adding analysis time.

All the operator needs to do is put a representative amount of sample (2 to 4 grams) in dry form in a 260mL bottle without the need of accurate weighing. After the bottle is placed in the oven, the system is started by lowering a handle that pierces the bottle with a needle. The remaining steps in the process are completely automated, including precise dosing of pre-heated solvent for full sample dissolution. Temperature is monitored and controlled accurately at all key points. Separation of soluble fraction from the crystalline matrix takes place in a TREF column, and each part of the sample is injected into the integrated detectors for analysis. At the end, the needle and lines are rinsed also automatically, leaving the instrument ready for a new analysis. All the information is finally displayed in a single electronic report generated by the software.

For its complete automation, simple operation, and for delivering precise and comprehensive results, CRYSTEX® QC represents a step forward in technology for the automation of Soluble Fraction determination in polypropylene resins.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia