Analytical Instrumentation

XRF and XRD Preparation? - Why not try the McCrone Micronising Mill?

Jun 20 2012

The McCrone micronising mill - is used throughout the world in laboratories where integrity of the sample is of paramount importance, it is an indispensable tool for leading geologists, chemists, mineralogists and materials scientists in analysis of crystalline solids.

The McCrone Micronising Mill is a proven solution for overcoming the many problems associated with grinding particles for X-ray diffraction, X-ray fluorescence and infra-red analyses. It minimises contamination, time, cost and mess of sample preparation. What makes it so effective is the unique grinding action of the cylinders producing both linear contact blows and planar shearing.

The result is a short grinding time with virtually no sample loss, as well as exceptionally even particle size distribution. There is virtually no chemical degradation of the particles and a significant reduction in the crystal lattice disturbance.

The McCrone Micronising Mill rapidly reduces samples by a unique vibratory grinding action. Each element within the grinding

vessel moves with respect to its neighbour so as to produce linear contact blows and planar shearing.

The McCrone Mill is particularly suitable for Carbides, Nitrides, Borides, Cement, Clay, Shale, Mica and

many other materials.

Features Include:

• Minimises sample damage and contamination

• Ensures narrow range, reproducible particle size

• Minimal maintenance

• Bench mounted

• Timer up to 30 minutes

• Choice of grinding elements

• Wet and dry grinding

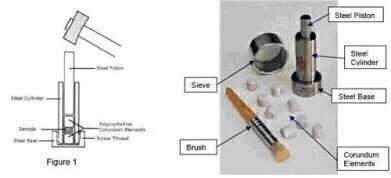

SAMPLE PREPARATION KIT

When required, initial material too large for the McCrone Mill can be rapidly and easily reduced to suitable sizes by the use of the sample preparation kit.

Each element within the grinding vessel moves with respect to its neighbour so as to produce linear contact blows and planar shearing.

The grinding vessel consists of a 125ml capacity polypropylene jar fitted with a screw capped gasketless polyethylene closure.

The jar is packed with an ordered array of forty-eight identical cylindrical grinding elements which are available in either Agate or Corundum. Depending on the material, grinding time is between 3 and 30 minutes and optimum grinding efficiency is usually achieved with 2ml of sample.

There is minimal particle damage to surfaces and the internal structure.

Principle of Operation

Dry sample of maximum 12 mm diameter and 40 mm length is placed inside the steel cylinder, between 2 Corundum pellets. The steel piston is the placed in the cylinder on top of the corundum pellets and given several sharp taps with a 1 kg hammer (not included in the kit). The crushed sample is then emptied out onto the sieve. The sieve oversize is returned to the percussion mortar for further processing until all particles will pass through the sieve. The steel base can be unscrewed from the steel cylinder for cleaning. A pair of Tungsten Carbide pellets is also available as an optional extra.

Weights and Dimension

Percussion mortar only: 108 mm high x 38 mm max diameter. Weight 410g

Percussion Mortar

Material: Stainless Steel

Closure Method: Screw Thread

Sample Materials

Carbides, Nitrides, Borides, Cement, Clay, Shale, Mica, Bone.

For more information on the McCrone Micronising Mill please click here

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Riyadh, Saudi Arabia

May 06 2024 Houston, Tx, USA