Analytical Instrumentation

How to determine Oily Residues and Hydrocarbons in LPG with one analyser?

Feb 18 2015

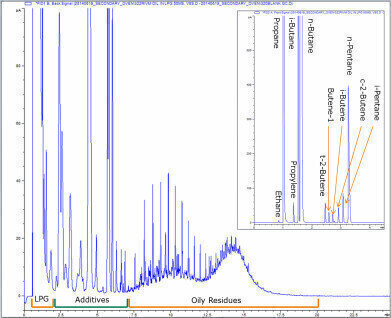

The GC methods ASTM D7756 and EN 16423 determine the oily residues in LPG based on a direct on-column LPG injection technique. Adding a liquid sampling valve and an external GC oven extends the residues analysis to report the hydrocarbon composition at the same time from the same sample cylinder.

Da Vinci Laboratory Solutions (DVLS) developed the direct, on-column LPG injection technique and introduced this as the DVLS Liquefied Gas Injector (LGI) in 2010. ASTM approved the LGI technology as the ASTM D 7756 standard test method for the analysis of oily residues in LPG in 2011 and this method was published as the European Standard EN 16423 in 2012.

Oily Residues in LPG

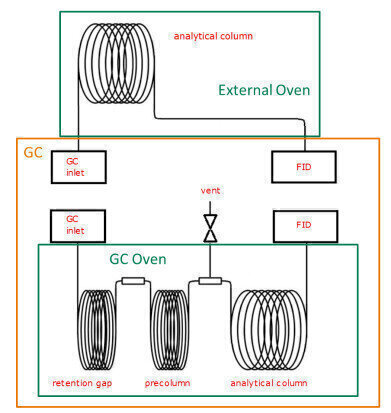

The ASTM D7756/EN 16423 application uses the Liquefied Gas Injector (LGI) configured on top of a GC together with a controller box. A pressure station injects the pressurised gas as a liquid directly onto the GC column by keeping the pressure at a constant level of 25 bar. This results in a representative sample injection of the LPG sample. The chromatographic analysis after the sample introduction is based on boiling point separation of the oily residues and contaminants.

Hydrocarbon Composition of LPG

The application dedicated to the hydrocarbon compositional analysis of LPG complies with ASTM D 2163 and ISO 7941. To combine the compositional analysis with the oily residues analysis the application was extended with a liquid sampling valve, a Split/Splitless inlet, an FID detector, an analytical column and an external oven.

A new application note describes the dual analysis of ASTM D7756/EN 16423 and ASTM D 2163/ISO 7941 within 30 minutes.

The DVLS Liquefied Gas Injector offers the petrochemical industry numerous benefits:

- Innovative sampling technique - A high pressure injection valve connected to an injection needle ensures a direct on-column LPG injection.

- High safety - The direct injection approach of the LGI eliminates the need for sample evaporation of the LPG.

- Representative sample injection – The Pressure Station allows to inject a representative sample of the pressurised gas as a liquid.

- Wide application range:

- Oily residues and light contaminants in LPG (ASTM D7756, EN 16423)

- Hydrocarbon composition of LPG (ASTM D 2163, ISO 7941)

- Elemental Sulfur in LPG

- Desulfurization additives in LPG: DIPA, MEA & DEA

- Inhibitors, additives and Dimers in Butadiene: ρTBC, VCH and NMP

- Natural Gas Condensate

- Fast analysis time of less than 30 minutes.

Download the application notes for a complete description of the various analyses performed with the DVLS Liquefied Gas Injector.

Digital Edition

PIN 25.1 Feb/March

March 2024

In This Edition Safety - The technology behind the ION Science Tiger XT - Safety with ammonia and LOHCs as hydrogen carriers Analytical Instrumentation - Discussion on new tribology te...

View all digital editions

Events

Apr 22 2024 Hannover, Germany

Apr 22 2024 Marrakech, Morroco

Apr 22 2024 Muscat, Oman

Apr 22 2024 Rotterdam, Netherlands

Apr 23 2024 Singapore